Home List your patent My account Help Support us

Child resistant closure for dangerous products

[Category : - OTHER- HEALTH- Life-saving; Fire-fighting]

[Viewed 3408 times]

In general terms, the system is based in a cap with internal and external threads, with different pitch and/or direction. The system considers also another piece, consisting in a safety ring, which locks the system when typical opening procedure is done. This ring lets the cap opening if the opening sequence and direction is met.

This invention is justified because is very frequent that kids or babies open containers and ingest medicines, toxic or dangerous products existing at home, schools or kinder gardens, that can be reached because adult un-care or because they reach places assumed as safe.

In these products we can find medicines in pills, liquid medicines and other, detergents, disinfectants products, cleaning products, lubricants, poisons, and many others detailed in the document below.

Daily in the world thousands of kids are intoxicated, and more than one hundred of them die every day.

The scope of application of the designed cap can be extended to other products of industrial use, to give more safety in their use.

Currently, the regulations of several countries like United States of America, United Kingdom, Australia and many others require the use of safety caps for products that can cause intoxication to kids or babies. In the same way organizations like WHO (World Health Organization) together with United Nations (ONU) and ILO and others of similar importance also require these caps or recommend them.

Currently exist some solutions used in this purpose, but the safety cap presented here has many advantages respect the existing safety caps. These advantages are related with the required sequence of opening, that is able to be used by persons with hand limitations or old people, tightness, ability for liquids, stiffness, strength, effective operation, cost, commercial application, innovation, and others detailed below.

The patent application for this closure was presented in Inapi (Chile) in 2013. This application is following the different steps, and has the priority to be presented in different countries by PCT.

An operating prototype is available.

To have this patent gives 20 years of exclusivity in this huge market, and many others in a non-exclusive way but with the brand positioned in the market.

Different alternatives of negotiation of this patent are considered. They include licensing, patent selling, and others.

PROBLEM TO BE SOLVED

Is very frequent that kids or babies open bottles and ingest medicines, toxic or dangerous products existing at home, schools or kinder gardens, that can be reached because adult un-care or because they reach places assumed as safe.

According to the World Health Organization (WHO), every day are done thousands of calls to the intoxication control centers in the world, and every day die around 125 kids because intoxication with medicines, drugs, toxic or dangerous products. Only in the USA, yearly around 60,000 kids are attended because uncontrolled ingest of medicines, toxic or dangerous products that were reached by them. Around 56 kids under 14 years old die every year in USA, and 35 of them have 5 years or less.

Some of these products are:

Medicines in pills

Liquid medicines

Disinfectant medicines

Detergents

Disinfectants products

Cleaning products

Cosmetics products

Lubricants

Tools complements

Fuels

Poisons

Paintings

Others

The invention is a child resistant closure applicable to many of these products, which is more difficult to open by kids or babies, but not for adults. This is a requirement of regulations in many countries, and is very recommended by international organizations.

Its application scope could be extended to other products of industrial use, to give more safety in their use.

TRENDS

Currently the regulations in several countries require the use of safety closures for products that can cause intoxication to kids or babies.

For example, the United States Product Safety Commission, official institution of USA, requires the use of safety closures for at least a list of medicines and products well defined. The results have been very successful, reducing from 216 kids die in 1972 to 28 in 2010 in USA, or 35 in average the last years.

Several European countries also require the use of safety closures. For example, the United Kingdom requires from 1977 that some medicines, like Aspirin and Paracetamol for adults, be sold in child resistant packaging. A voluntary agreement between doctors and pharmaceuticals to sell any solid medicine in this type of packaging was done in 1981, especially for antidepressant, digoxin, iron and others.

In Oceania, countries like Australia or New Zealand require safety closures for some products and medicines.

Like them, many other countries require and other suggest the use of safety closures for medicines and dangerous or toxic products that can be reached by kids or babies. Because their leader status, some countries that now do not require these caps will do it in the future.

Organizations like World Health Organization (WHO) together with ONU and ILO recommend the use of these caps for medicines and toxic products. Other organizations like poisonprevention.org, safekids.org, the Kids Hospital of Philadelphia, the Centers for Disease Control and Prevention of USA, and many others also recommend these caps.

EXISTING SOLUTIONS

Currently exist some solutions aimed to the protection against uncontrolled ingest of medicines by kids.

The most known solution is shown in the following figure. To open this cap is necessary to push down and simultaneously turn the cap. The system is based in an external hard cap which pushes an internal flexible cap. This internal cap closes the bottle.

DESCRIPTION OF THE DESIGNED CHILD RESISTANT CLOSURE

The invention consists in a child-resistant closure, to be used in bottles or containers containing dangerous products like drugs, toxic liquids, chemical products or similar, more difficult to open than normal caps by kids or babies, and at the same time friendly for senior people.

In general terms, the system is based in a cap with internal and external threads, with different pitch and/or direction. The system considers also another piece, consisting in a safety ring, which locks the system when typical opening procedure is done. This ring lets the cap opening if the opening sequence and direction is met.

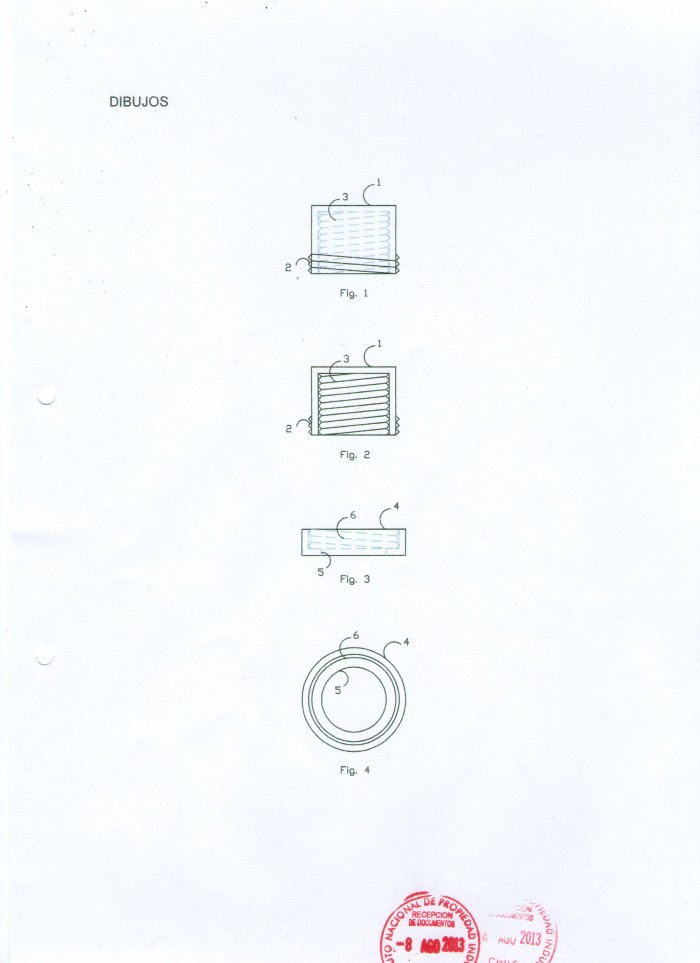

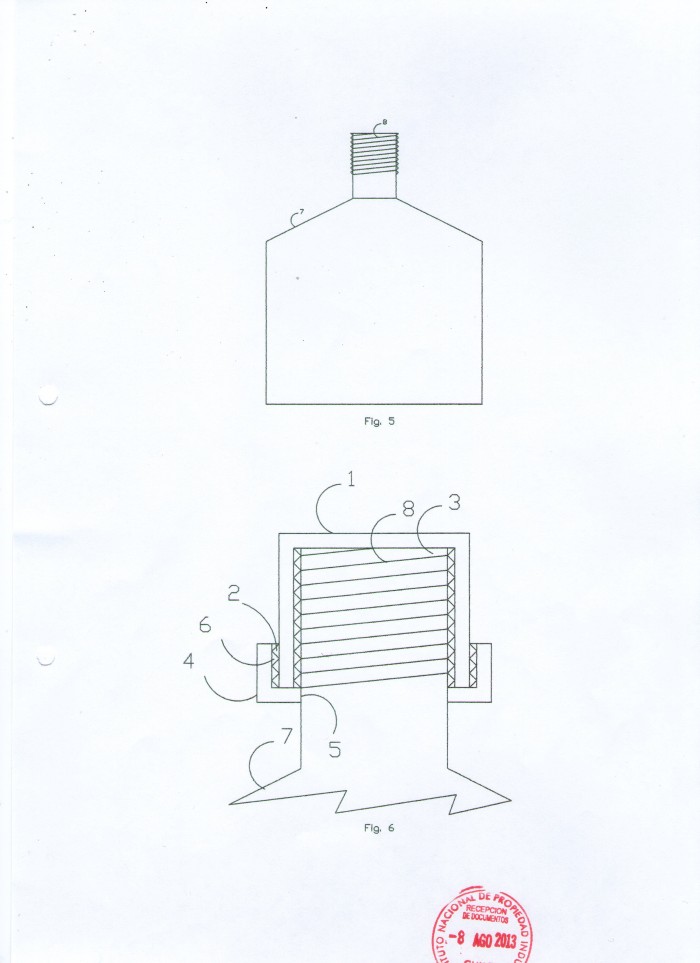

In a detailed way, the invention includes two pieces. (In the following description, numbers refer to parts shown in the figures 1 to 12).The top piece 1 is a cap with inner thread 3, which also has a zone with outer thread 2, in the open edge of the cap. Furthermore, the invention considers a lower piece 4 which is a cap with a hole of diameter adjusted to the neck without thread of the bottle or container 7. This cap has an inner thread 6 which is assembled with the outer thread 2 of the top piece 1.

The edge 5 of the hole in the lower piece 4 may have, or may not have, a triangular cut 9. The existence of this cut 9 helps in the process of assembling the lower piece 4 in the bottle 7.

For the assembly of this invention, first the lower piece 4 is assembled in the bottle neck to further below the zone with thread 8. The piece is assembled with the thread 6 zone up. To mount this piece a certain pressure or force is required, because the edge 5 of the hole will be blocked by the threads 8 of the bottle neck. Once the lower piece 4 is assembled, place the top piece 1 by rotating the cap, which will close the bottle like any normal cap. Then, the lower piece 4 must be raised and turned, so as to assemble the top piece 1 in the outer zone with thread 2 of this piece.

It is necessary that the internal thread 6 of the lower piece 4 and therefore the external thread 2 of the top piece 1 be of different pitch and / or direction than the internal thread 3 of the top piece 1.

Thus, when the invention is assembled, when somebody try to open the cap by turning the top piece 1, both pieces 1 and 4 will turn and raise together, but they will do it only until the edge 5 of the hole of the lower piece 4 butts with the thread 8 of the neck of the bottle or container. In this moment will be very difficult to open the cap, and will require a big force to do it. Having threads with different pitch or direction, as indicated above, and pretending to open the cap, the system will tighten even more than it was.

To properly open this cap, the person first must turn the lower piece 4 until it is released from the upper piece 1. Then he should turn the top piece 1 and open the bottle or container.

To properly close this cap, the person must place and turn the top piece 1. Then take, raise and turn the lower piece 4, which normally remains around the neck of the bottle or container, and is assembled with the upper piece 1.

Attached are 12 figures to explain the current invention. Figure 1 shows the top piece 1 in elevation. This figure shows the zone with external thread 2, and can be seen the internal thread 3 with smooth dotted line. In this case the threads have different direction.

Figure 2 shows the top piece 1 in section. This figure shows the zone with external thread 2 and internal thread 3.

Figure 3 shows the lower piece 4 in elevation, and is seen with smooth dotted line the edge 5 of the central hole and the internal thread 6.

Figure 4 shows the lower piece 4 in plant, and is seen the edge 5 of the central hole and the internal thread 6.

Figure 5 shows the bottle or container 7 with its neck with thread 8.

Figure 6 shows a detail of the assembled system. This figure shows that the lower piece 4 has been assembled under pressure, and the edge 5 of the central hole is under the thread of the container 8. The top piece 1 has been placed, in such way that the internal thread 3 fits with the thread of the container 8. The lower piece 4 has been assembled to the top piece 1, in such way that its internal thread 6 fits with the external thread 2 the top piece 1.

Figure 7 shows one alternative, consisting in an edge of the hole with a triangular cut 9, which facilitates the assembling of the lower piece 4 in the neck of the bottle or container.

Figure 8 shows an application example, showing the opening sequence for the case when the threads have different pitch and the same direction. First turn the lower piece 4 in one direction and release it. Then turn the top piece 1 in the other direction and opens the container.

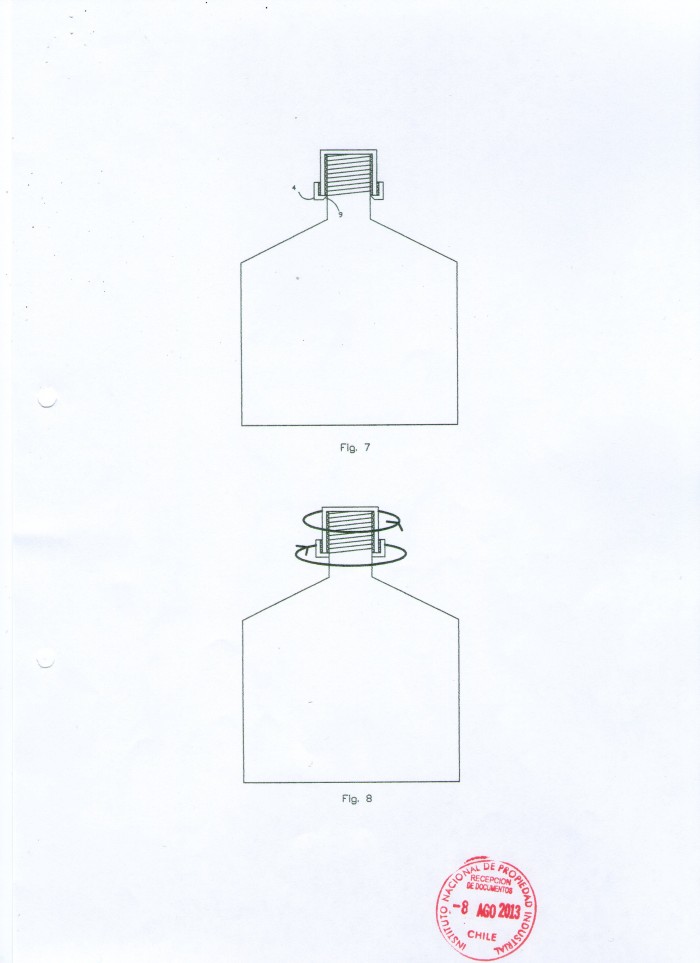

Figure 9 shows the lower piece 4 with the alternative triangular edge 10, which difficults the handling by kids or babies.

Figure 10 shows the lower piece 4 with the alternative curved edge 11.

Figure 11 shows the lower piece 4 with the alternative triangular edge and small points equally spaced 12, that difficult the handling by kids or babies.

Figure 12 shows the lower piece 4 with the alternative curved edge and small equally spaced points 12, that difficult the handling by kids or babies.

There is a case similar to figure 1, but with threads having the same direction.

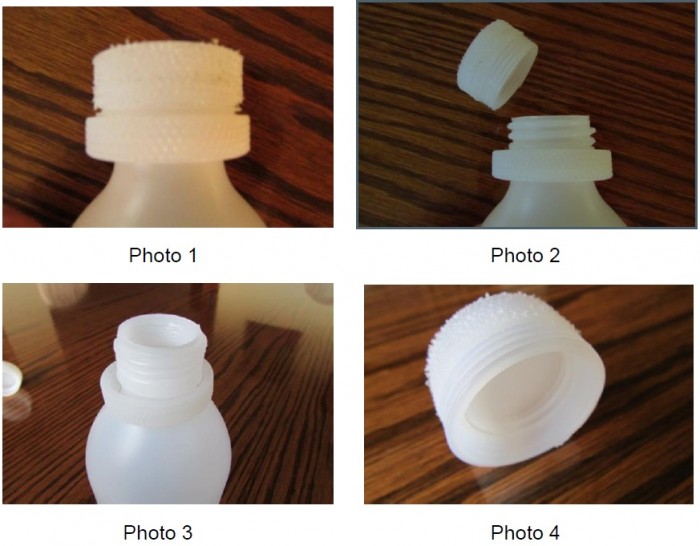

These are some photos of the prototype.

Photo 1 Photo 2

Photo 3 Photo 4

Photo 1 shows the assembled child-resistant closure. The bottom ring is fixed to the upper cap.

Photo 2 shows the child-resistant closure opened.

Photo 3 shows the container with its neck and thread, and the bottom ring with its internal thread. In this position the bottom ring is loose.

Photo 4 shows the upper piece, consisting in a cap with internal thread, and an external zone with thread.

There is a video available in Link

ADVANTAGES RESPECT EXISTING SOLUTIONS

Currently exist some solutions to solve the same problem. The most known solution is the “Push down and turn” child resistant closure.

Compared with this closure, the new child-resistant-senior-friendly closure has several advantages. Some of them are the following:

It requires to turn two pieces to open the new safety closure, which must be turned in a defined sequence and direction: first the lower piece and then the top piece must be released.

Having threads with different direction and/or pitch, if the opening is intended turning the top piece, which for size naturally will be the first option, the system will not open. If threads with same direction and different pitch are used, it requires different directions to open the cap. Real tests show that sometimes kids try to turn both pieces simultaneously, but the system will not open in this case.

Some regulations, like from USA, UK and others, acknowledge that the existing cap is very difficult to be opened by senior people or people with hands limitations, because it requires the use of both hands. In this case these regulations release the obligation of safety caps, and open the possibility for kids to be intoxicated. The new closure is not too difficult to be opened by people with only one hand (see video). For senior people the new closure is not more difficult to be opened than with a normal cap.

The new closure could be fabricated for many existing containers. The existing cap is difficult to be applied to big containers, because is not easy to insert the internal cap in the external cap for big sizes.

This advantage lets the producers include the solution only changing the cap.

The tightness of the new closure is better than the existing cap, because in the existing cap the sealing element is the internal one, which is thin, soft, flexible and then could be broken. In the new closure the sealing element is as rigid and resistant as you want. In the existing cap the external element does not contribute to the strength neither to the tightness because is only to push the internal cap and also has a clearance. In the other hand, in the new closure the ring contributes to the strength and partially to the tightness. This makes the new cap especially adequate for containers having liquids or solids that could be affected by the air, like almost any drug.

For some products is not proper to use a thin cap like the existing cap, requiring a hard, rigid and strong cap like new closure.

In the existing cap, sometimes partially fails the system that let the external cap push the internal cap.

The new system avoids involuntary bad closure, because the loose ring warns. Putting the ring you will be sure that sealing element is well positioned.

The application scope of the new cap is beyond the products related with kids. It also applies to industrial safety.

The quantity of material to fabricate the new cap is lower than existing cap, so the fabrication cost is lower.

The optional triangular edge and/or points in the bottom piece have the advantage that make more difficult to handle by children or babies.

Because it is a new solution, it could be used also by parents whose children have learned to open the existing cap.

Since the edge of the hole of the bottom piece is adjusted with respect to the neck of the bottle, this piece remains typically together with the container or bottle, so there is no risk of losing.

To rotate the lower piece requires more finesse because it is thin, and the best way to do this is using only the thumb and index finger, forming a kind of C with these fingers, which is more difficult for a kid or baby.

COST BENEFITS

The price of the product is very higher than the production cost. The value of the product is mainly in the innovation and in the safety benefit that gives, very higher than its production cost.

Compared with a traditional cap, the cost of this solution has a marginal difference. Compared with the existing safety cap, the cost of the new solution is lower than the existing one.

Also, a father would be willing to pay much more than this marginal extra-cost for their kids’ safety and health.

INTELECTUAL PROPERTY

The patent application for this closure was presented in Inapi (Chile) in 2013. This application is following the different steps, and has the priority to be presented in different countries by PCT.

NEXT STEPS OF THE PROJECT

The following steps are considered:

To continue with the patenting process in Chile and PCT

To test the prototype

To negotiate the patent with the inventor

To patent the solution world wide

KEY WORDS

child baby babies kid kids resistant proof closure cap caps package packages packaging poison poisons toxic safe safety secure care

Financial information

POTENTIAL AND TARGET MARKET

The potential market of this safety cap is very huge. The designed safety cap is applicable worldwide to a wide variety of products. For several of these products, each year are sold thousands of millions (billions) of units, reaching several billions of units as potential market. Pretend to obtain only a percentage of this market is a huge target market.

For example, only the consumption of chlorine, for home, in the developed countries is around 2,500 million of cans yearly. The consumption in other countries is very important also, with a huge total market only for this product.

The market for other products, like drugs, medicines, detergents, and several of mentioned above, are similar or higher than the chlorine.

This solution could be offered to several producers of dangerous products or drugs existing in the industry. Also is possible to produce the caps for substitution of the originals to sell them directly to public, and is possible to produce containers with this safety closure to sell them directly to public. These three models are compatible and could be done simultaneously, because they are not exclusionary.

To have this patent gives 20 years of exclusivity in this huge market, and many others in a non-exclusive way but with the brand positioned in the market.

PATENT NEGOTIATION

Several alternatives are considered. They include patent selling, patent licensing, and others.

CONTACT INFORMATION

Mr José García

Cel – Whatsapp (+56-9) 99845027

Email [Use the button below to contact me]

Patent publications:

Patent publications: No published information

No published informationAsk the inventor for a copy of the filed application

Asking price:

Make an offer

Make an offer

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2025-11-26 3:55:51, Patent Auction Time.

Great invention

Great invention