Home List your patent My account Help Support us

Traction Powered Machine - Alternative Energy

[Category : - RENEWABLE ENERGY]

[Viewed 3609 times]

While summit conferences tackling these Global conditions continue to rage feverishly, everyday, throughout the world, there are millions of tons of free and clean energy that remains untapped – the energy coming from vehicles which use regulated and refined fossil fuel.

Going by the mass and speed with which each vehicle hugs the streets surfaces we could just figure out that there are indeed millions of tons of this energy that could be harnessed to produce hundreds of billions of dollars worth of electricity.

It is for this reason that I am introducing my machine, the traction-powered which can transform forces produced by running vehicles in conjunction with their mass and acceleration.

Ernesto Ganaden

Inventor

[Use the button below to contact me]

09065053448

Field of the Invention

The invention relates generally to the use of an alternative energy

source, and more particularly to a machine that utilizes an energy source

that is free and clean.

Background of Related Art

The use of sustainable source of energy is an art as old as civilization

Itself. Because of the need to produce his basic needs with much less

effort, man has eventually discovered the potentials of wind and water

to turn his simple machines. Thus, the windmill and the water turbine

were born. Later on, solar power and the use of coal to produce steam

came into being.

The discovery, however, of fossil fuel is considered a breakthrough

In the quest for a more sustainable energy source. Not long after, taking

cue from its immense reliability, the internal combustion system was

Invented.

But as automobiles and power generating plants, which are the

direct beneficiaries of the fossil fuel, began to proliferate worldwide, so

did the poisonous gas that the burnt fuel emitted at an alarming rate.

R,A. 9513, also known as the Renewable Energy Act, was enacted

Into law last January 2009, and said to be the most comprehensive

renewable energy law in Southeast Asia.

The problem, however, that arises in the search and development

of these renewable sources of energy is the difficulty to locate and

utilize said sources, and the prohibitive cost it will incur considering

the government’s lack of fund for such exploration.

Purpose of the Invention

The purpose of the invention is primarily to solve the problem

mentioned above by providing for a traction-powered machine.

Another purpose of the present invention is to utilize a free

and clean source of energy that would enable the electric power

generator or other conventional machines to run without the use

of harmful materials.

Another purpose of the present invention is to provide for a

traction-powered machine that is disposed inside a bunker along

a road or the like, and comprising a bar assembly wherein said bar

assembly is provided with a steel bar that protrudes through a steel

frame laid across the surface of said road or the like; together with

said bar assembly is a pair of trapdoors provided on both sides of the

steel bar, and attached at both ends of the base of the steel bar is a

pair of power springs, and also attached at the middle of the base of

said steel bar is a connecting rod that links said steel bar to a gear

assembly which consists of a power pinion and a gear that is mounted

on a shaft which delivers power to the wrapping connector assembly.

Another purpose of the present invention is to provide for a

traction-powered machine whose maximum efficiency is achieved with

a provision for a plurality of said machine wherein as many traction-

powered machines as possible are disposed side by side in rows opposite

each other and in between said rows are one or more wrapping

connector assemblies.

Another purpose of the present invention is to provide for a

traction-powered machine which is equipped with a self-preservation

mechanism wherein said machines in one row have their gears turned

via the ring pawls by the direct force caused by the impact between

tires and the steel bars while said machines in the opposite row have

their gears turned via the ring pawls by the pulling effect of the power

springs retracting to their normal position.

Also another purpose of the present invention is to provide for

a traction-powered machine that is versatile, in which case said machine

can be used to operate conventional machines other than the electric

power generator.

Also another purpose of the present invention is to provide for a

traction-powered machine that is simple in construction and is made of

locally available materials.

Still another purpose of the present invention is to provide for

a traction-powered machine that is easy to operate and requires little

attention.

Other purposes and advantages of the present invention for a

traction-powered machine will become apparent upon reading of the

following detailed description taken in conjunction with the

accompanying drawings.

Brief Description of the Drawings

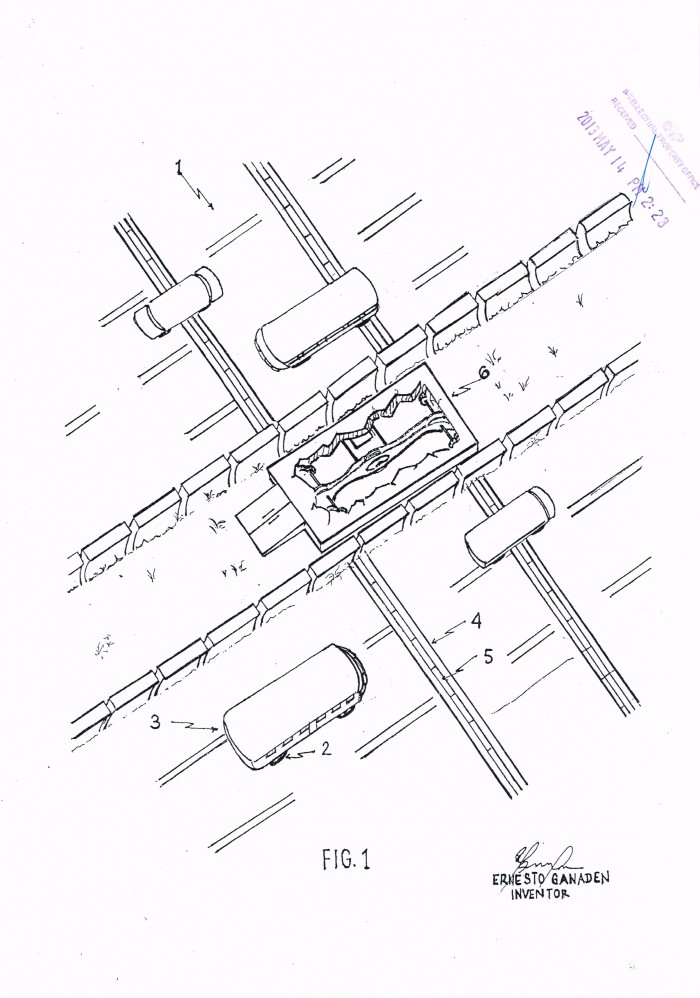

Figure 1 is a bird’s eye view of a road or the like showing the

present invention’s pair of steel frames and a number of steel bars

within said steel frames.

Figure 1 also shows a cross-sectional view of the powerhouse

wherein the present invention’s partial mechanism is situated;

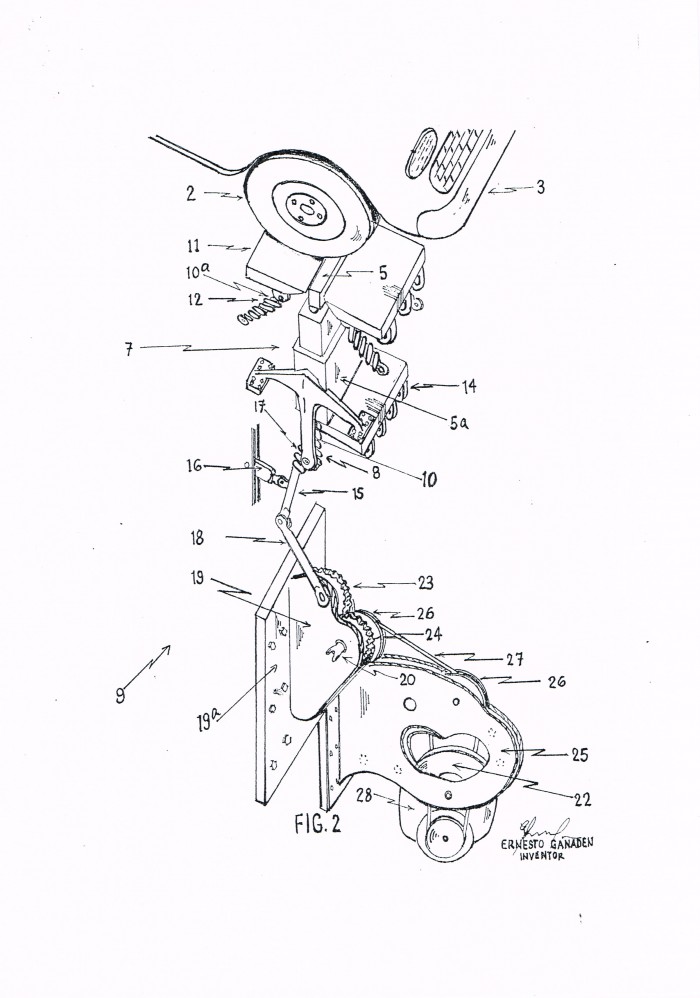

Figure 2 is an elevational perspective view of the present

invention’s single , detached traction-powered machine;

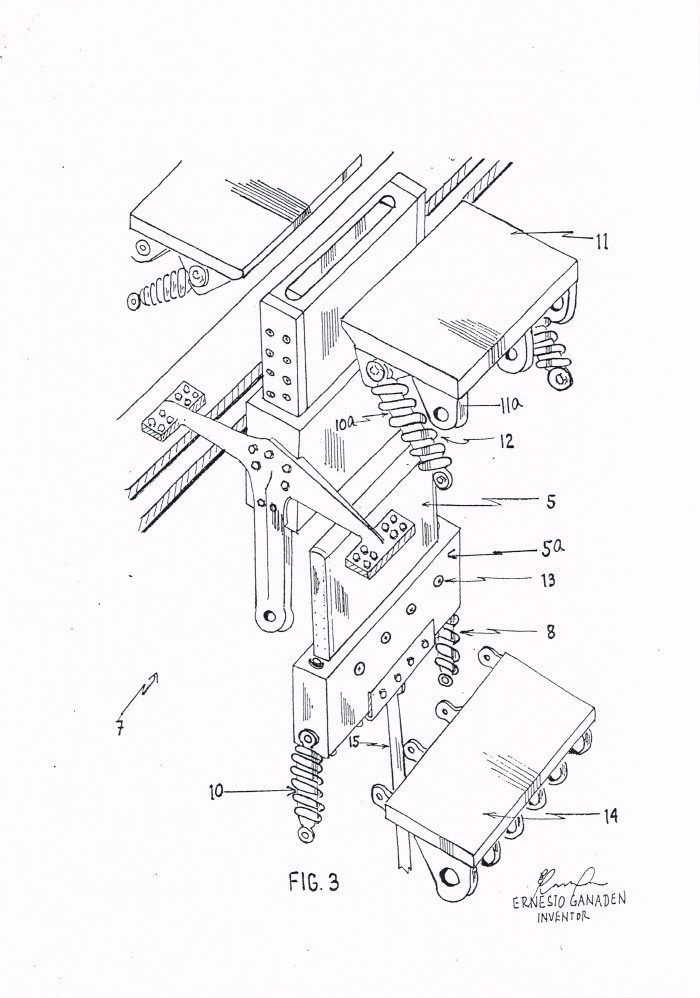

Figure 3 is an exploded view of the bar assembly showing some

of its essential parts and accessories;

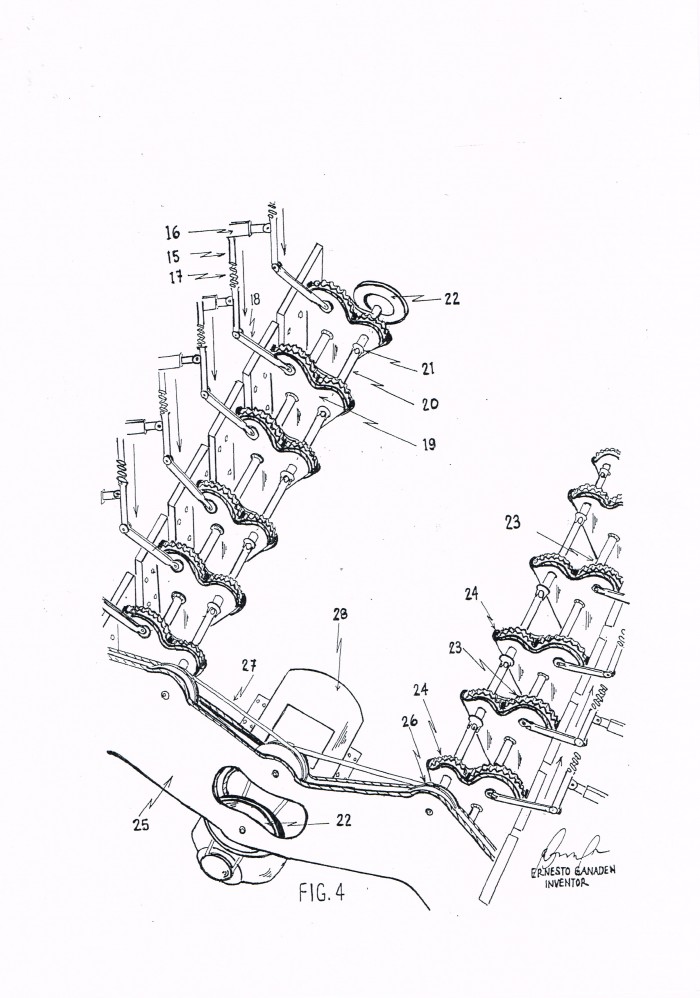

Figure 4 is a perspective view of the present invention’s disposition

of the interconnected traction-powered machines and its provision for

a self-preservation mechanism;

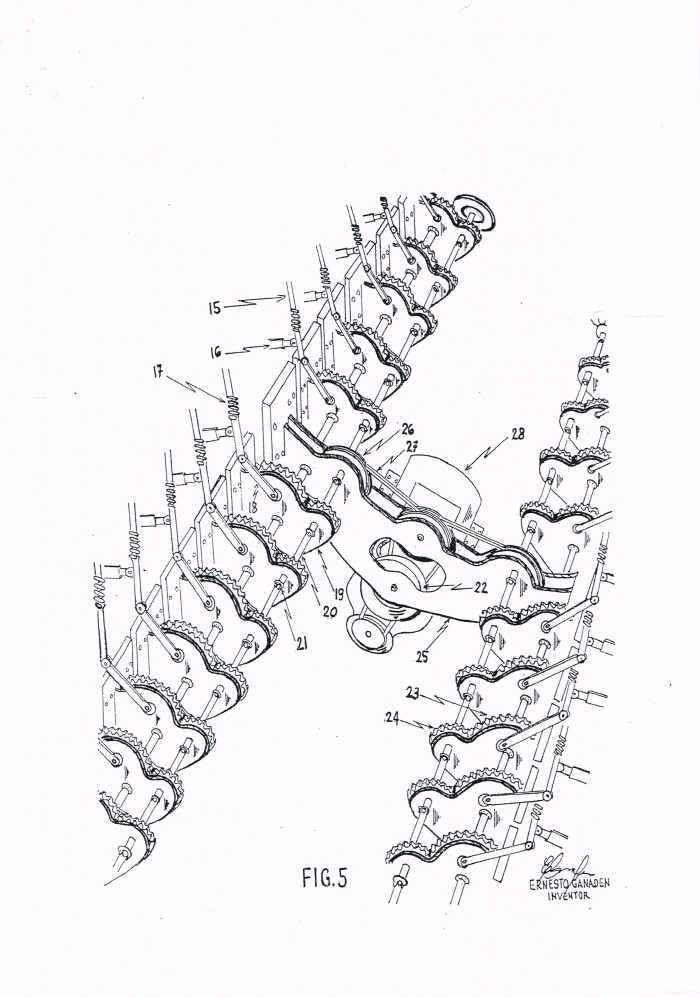

Figure 5 is a perspective view of the present invention’s disposition

of a high-density mechanism; and

Figure 6 is an illustrative view of the gear assembly.

Detailed Description of the Drawings

Referring now to the drawings where some essential parts of the

present invention is designated throughout, there is shown the bird’s

eye view (Figure 1) of a road 1 or the like to depict the purpose of the

present invention which is the use of a free energy source and more

particularly its function which is to utilize the energy coming from

the tires 2 of a running vehicle 3 as illustrated by the steel frames 4

laid horizontally across the said road 1 or the like, and within said steel

frames are enclosed a number of the steel bars 5.

Said present invention for a traction-powered machine which is

generally designated as 9 (Figure 2) will start to work when the tires 2

of a running vehicle 3 run over a plurality of bar assembly 7, each

housing a steel bar. Said bar assembly 7 is bolted on to the beams

just below the surface of the above road 1 or the like. The linear force

created by the impact between the tires 2 and the steel bar 5 is then

absorbed by the pair of opposing power springs 8 wrapped around a

respective vertical shock absorber 10 that are attached to both ends

of the base 5a of the steel bar 5.

To enhance the present invention’s performance, a pair of

opposing trapdoors 11 is pivotally disposed at the sides of said steel

bar 5, each with suspension spring 12 and a plurality of diagonal

shock absorbers 10a fixed beneath thereof and are bolted on to the

steel frame 4 through hinges 11a provided at the bottom edge of said

trapdoors 11. This will allow heavier vehicles to depress said steel bar 5

further down, thus creating more force.

To further enhance the present invention’s performance, the

height of the steel bar 5 which is reciprocating in said base 5a can be

adjusted by loosening the screws 13 (Figure 3) provided thereto for

holding the said bar 5 and tightening them after the desired height is

obtained.

Also provided securely at the bottom of the base 5a of the steel

bar 5 is a stabilizer 14 to prevent said steel bar from tilting sideways

whenever the tires 2 hit said steel bar off-center.

Referring back to said force created as earlier described, said force

would travel along the connecting rod 15 (Figure 4) projecting

downwardly from the bottom of said base 5a. Said connecting rod 15

is held firmly by a pivoted latch 16 next to the cushion spring 17 provided

there to. The lower end of said connecting rod 15 is pivotally connected

to the lever 18 and down the gear assembly 19 that is bolted on to a

steel frame 19a inside a bunker (not shown) disposed inside the

powerhouse 6.

Inside said bunker, a number of the traction-powered machine 9

can be disposed with their shafts 20 interconnected by universal joints

21 all the way to the rear end of each row where a flywheel 22 is

attached and whose function is to gather inertia and to ensure smooth

and continuous rotation of the shafts 20.

Said gear assembly 19 which is disposed below said bar assembly

5, consists of a power pinion 23 where a torque is created by the linear

force brought about by the lever 18, in which case said linear force is

transformed into a rotary force; a mating gear 24 is engaged with said

power pinion 23 and is mounted on the shaft 20.

The rotary force is transmitted to the wrapping connector assembly

25, disposed adjacent to said gear assembly 19. Said wrapping

connector assembly 25 consists of at least one power wheel 26

connected to said mating gear 24, and to at least one flywheel 22 that is

engaged with a power generator or the like via power belts 27.

Figure 4 and 6 show another embodiment of the present invention

which provides a self-preservation mechanism wherein, as indicated by their respective arrows, said machines in one row have their power

pinions 23 turned via the ring pawls 23a by the direct linear force coming

from the impact between the tires 2 and the steel bar 5, while said

machines in the opposite row have their power pinions 23 turned via the

ring pawls 23a by the pulling effect of the power springs 8 retracting to

their normal positions in order that said pulling effect would cancel the

jolts caused by the said impact which is equivalent to a blast in an

internal combustion engine.

Maximum efficiency of the present invention will be achieved in

such a way that provides for a high-density mechanism (fig. 5)

wherein as many traction-powered machines 9 as possible can be

disposed side by side in rows opposite each other with one or more

wrapping connector assemblies 25 provided in between them.

It is to be understood that while certain elements of the present

invention have been illustrated and described, it is not limited thereto

except insofar as such limitations are included in the following claims

and allowable functional equivalents there of.

Claims:

A Traction-Powered Machine adapted to drive a power

generator or the like and disposed along a road or the like, said

traction-powered machine comprising a bar assembly, a gear

assembly disposed below said bar assembly and a wrapping

connector assembly disposed adjacent to said gear assembly; said bar

assembly having a steel bar, a pair of opposing trapdoors pivotally

disposed at the sides of said steel bar, a base provided there of where

said steel bar is reciprocating, and whose height is adjustable through

the screws provided thereto, a connecting rod projecting downwardly

from said base, and a lever pivotally connected to said connecting rod;

said gear assembly having a power pinion connected to said lever, and a

mating gear engaged to said power pinion; said wrapping connector

assembly being defined by at least one power wheel and a belt

connected to said mating gear, and a flywheel being belt-driven by

said power wheel.

2. A traction-powered machine according to claim 1 wherein said

bar assembly further comprising suspension springs with a plurality of

diagonal shock absorbers fixed beneath said trapdoors, a stabilizer

provided securely at the base of said steel bar, and a pivoted latch

holding said connecting rod.

3. A traction-powered machine according to claim 1 wherein

said gear assembly is bolted on to a steel frame provided thereof.

4. A traction-powered machine according to claim 1 wherein

said wrapping connector assembly further comprising at least one

power wheel, connected to said mating gear, and to at least one

flywheel through power belts thereof.

5. A traction-powered machine according to claim 1 wherein

a plurality of bar assemblies are interconnected to respective gear

assemblies driving at least one wrapping connector assembly that is

coupled to at least one power generator or the like.

ABSTRACT

A Traction-Powered Machine adapted to drive a power generator

or the like and disposed along a road or the like, said Traction-Powered

machine comprising a bar assembly, a gear assembly disposed below

said bar assembly, and a wrapping connector assembly disposed

adjacent to said gear assembly; said bar assembly having a steel bar,

a pair of opposing trapdoors pivotally disposed at the sides of said

steel bar, a base provided thereof where said steel bar is reciprocating,

and whose height is adjustable through the screws provided thereof,

a connecting rod projecting downwardly from said base, and a lever

pivotally connected to said connecting rod, said gear assembly having

a power pinion and a mating gear engaged to said power pinion; said

wrapping connector assembly being defined by at least one power

wheel and a belt connected to said mating gear, and a flywheel being

belt driven by said power wheel.

Financial information

I am particularly looking for interested parties for licensing or partnerships.

Patent publications:

Patent publications: No published information

No published informationAsk the inventor for a copy of the filed application

Asking price:

Make an offer

Make an offer

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2025-11-26 3:47:27, Patent Auction Time.

Great invention

Great invention