Home List your patent My account Help Support us

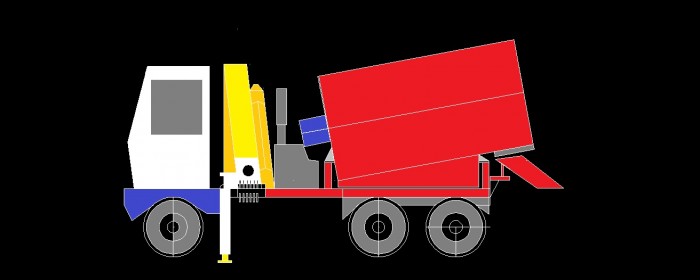

SCMD TRANSIT MIXER FOR PRODUCTION & TRANSPORTATION OF CONCRETE

[Category : - MECHANICAL ENGINEERING- Construction Processes & Equipment]

[Viewed 7844 times]

At the same time, a huge opportunity is also there in stationary plants having capacities more than 100 cubic meter per hour involving the SCMD technology, which reduces the size of the equipment, power required and eliminates belt conveyors OR skip buckets and present a complete batch-mix plant made fabricated out of steel without any belt conveyors or skip buckets.

Financial information

Either Licensing on Royalty basis / Assignment.

Terms can be negotiated.

We have started commercially producing OM transit Mixers after filing of the INDIAN as well as the International application. The Commercial production was started since JUNE 2012 and a no. of equipment have been working in the Indian Market. A no. of videos are available on YOUTUBE. One can find the working videos by entering "OM TRANSIT MIXER" in the YOUTUBE search.

We have also launched a conversion scheme where in a normal conventional transit mixer is converted into a mobile batching-mixing plant CUM transit mixer. Which has received a good response. One can see the conversion video on YOUTUBE. Even if we consider a 5% market for conversion in INDIA, it amounts to a turnover of more than 100 crores.

Since the central mix plants are completely eliminated, there are no overheads and dead investments in land/ foundations/ d.g. sets apart from skilled manpower. The invention thus results in huge savings in CAPEX ( capital Expenditure) as well as OPEX ( operational expenditure.) It also brings huge flexibility as one can easily shift these machine from one location to another as they are 100% mobile and are mounted on commercial trucks. They have been approved by RTO ( Road Transport Office) in India and can ply inside city limits. The OM transit mixers are simple machines to make as they can be made with a simple mechanical drive as well. Even the control panel works on 24 Volt truck batteries.

The end user can free his investment in one machine by producing & transporting only 3000 cubic meter of concrete. ( considering only the labour cost in INDIAN context.) and one machine can do 1500 cubic meter in one month considering little travel and a quantity of 50 cubic meter per day.)

In case of conventional transit mixer, the transit mixer keeps the mix alive by gravitational forces created due to continuous rotation of the mixing drum. However the OM (SCMD) transit mixers are provided with a unique design of spiral blades which mix the concrete similar to a twin shaft mixer, in a forceful manner and within a very short time. The mixing in OM transit mixer is a phenomenon dominated by the pitch and the directional movement due to L.H. & R.H. spirals. In conventional transit mixer, the mixer has to be rotated in forward & reverse in order to mix & discharge. This involves complete stopping of drum rotation while the direction is reversed. Which necessitates use of hydrostatic drive. However in case of OM (SCMD) transit mixers, the shaft rotates in only one direction but the material inside moves in multiple directions therefore resulting in homogeneous mix at the same time eliminating the need of a hydrostatic drive. A simple mechanical drive achieves a much higher efficiency and is easy to maintain.

The OM transit mixers save a huge amount of diesel which is otherwise wasted in running the stationary plant and re-handling the raw materials. The main saving includes the followings: 100 % saving on the diesel fuel required by the high power diesel generator set required to run the batching & mixing plant.

The savings to the end user are as follows :

1. No dedicated land required for central mix plant ( huge CAPEX saving)

2. no stationary plant is required. ( huge CAPEX saving)

3. No foundations required ( No dead investment)

4. No diesel gen-set is required ( huge CAPEX saving)

5. No conventional transit mixers are required ( Huge CAPEX saving)

The OPEX savings are :

1. 100% saving on Diesel OR power required to operate the stationary plant.

2. 100% saving on the maintenance cost of the stationary plant.

3. no skilled manpower required.

4. no re-handling of raw materials

Advantages over self loading transit mixers presently in the market :

1. OM transit mixers are designed for mounting on commercial trucks unlike the presently available self loading mixers, which are required to be mounted on custom designed trucks.

2. since the OM transit mixers are mounted on commercial trucks, the travelling speeds are higher.

3. The OM transit mixers have a forceful mixing action and hence can feed a concrete pump in continuous operation unlike the presently available self loading mixers, which have the reversible mixers.

4. The presently available self loading transit mixer has a limited capacity bucket and the machine has to move forward & reverse and to each material to feed itself which delays the cycle time & the hourly productivity. Wherein the OM transit mixers are fed at one single location and hence their hourly productivity is almost double than similar capacity self loading transit mixer.

5. The diesel consumption is lower in case of OM transit mixers as the OM transit mixers have the mechanical drive and the engine is run at a much lower rpm compared to the presently available self loading mixer.

6. one single loader can feed a no. of OM transit mixers. However each self loading transit mixer has to be provided with its own loading attachment.

7. The hydrostatic drive of presently available self loading transit mixers result in higher capital cost compared to a simple mechanical drive of OM transit mixers apart from the advantage of simple maintenance of the mechanical drive.

8. the total CAPEX for a small loader with a OM transit mixer mounted on a commercial truck is still lesser than that for a self loading transit mixer.but the output of OM mixer is almost double than that of a self loading transit mixer.

Kindly contact for details on cost comparisons of :

1. OM transit mixers & conventional Ready-MIx

2. OM transit mixers for concrete roads

3. OM transit mixers for continuous pumping

For the consumer the OM transit mixer quality advantages are:

1. Higher mix consistency due to a vary large batch size compared to a small/ medium capacity stationary plant.

2. Higher tolerance limit due to the very large batch size.

3. fresh concrete made available to the pour- site so no hot loads.

4. machine easy to maintain due to only one moving part.

Asking price:

Make an offer

Make an offer

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2025-12-21 16:07:21, Patent Auction Time.

Patent publications:

Patent publications: WO 2013065060

WO 2013065060 Great invention

Great invention