Home List your patent My account Help Support us

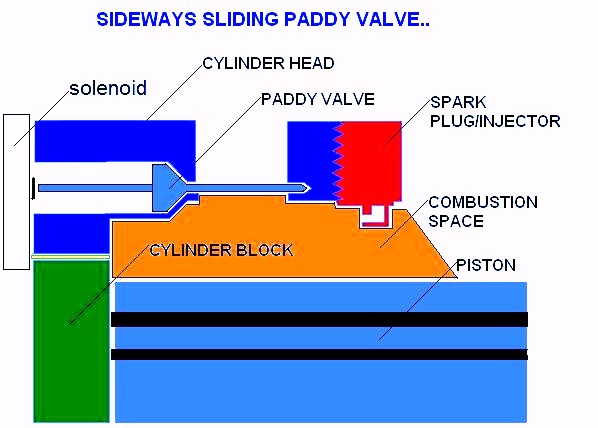

Sideways sliding inlet/ exhaust valves, springless, camless.

[Category : - Motors]

[Viewed 3451 times]

The Paddy Valve is a significant development in helping to solving the following issues with conventional valves:

1) Pumping losses.

2) The costly and timely repair involved with valve train failure.

3) A conventional valve itself constricts air flow into and out of the cylinder.

4) The range of valve timing is limited by the inevitability of piston contact in modern cylinder head design.

5) Conventional valve timing mechanisms cannot eliminate the problems of valve overlap.

6) Overcoming the valve bias resulting from valve springs requires significant energy from both the engine and starter motor.

7) Noise levels of conventional valve train design need to be reduced.

8) Reducing the unladen train weight of vehicles is increasingly important for future vehicle design and the mass of conventional valve train and cylinder head are significant.

9) Conventional valve design militates against efficient heat dissipation.

10) Inlet and exhaust port design is dictated by the design shape of the valve, limiting potential design opportunities.

The Paddy Valve offers the opportunity for significant improvements in all these areas, plus the following benefits:

1) The Exhaust Gas Recirculation would be achieved by simply closing the exhaust valve earlier in the exhaust stroke, retaining the required volume of exhaust gases in the cylinder.

2) Cylinders can be ?de-activated? by leaving all valves open in certain conditions.

3) At engine start-up, cylinders can be ?activated? sequentially allowing the possibility of smaller starter motors, batteries and alternators.

4) Current HCCI development could be enhanced with the ability for more extreme valve adjustment and control.

The design requirements of the Paddy Valve envisage the use of materials, technology and processes largely known and in current application within the automotive industry.

Conventional valves are energy inefficient - they protrude into the ports restricting gas flows and require a bias to operate. Current valve train design has severe restrictions in terms of ultimate timing variability, and draws significant energy from the power unit. If the system fails severe engine damage is inevitable and repair is time consuming and costly.

In my design the valves are set low in the head and the head itself will be significantly shallower than a conventional head. This feature, combined with the solenoid/actuators being mounted on the side of the head will lead to an overall reduction in the under-bonnet height required to mount the drive-train together with a lowering of the overall centre of gravity.

Other potential benefits include the possibility of sequential activation or de-activation of cylinders, giving fuel and energy savings in different operating conditions such as when starting, idling or cruising.

With the greater range of valve variability inherent in my design the advancement of HCCI should be accelerated.

Many, if not all, of the technical principles required for my design to work are well established. The operation of the internal combustion engine remains unaltered, but the ingress of fuel and egress of exhaust is significantly improved, both in terms of the energy needed for the process to happen, and the controllability of the process itself.

I envisage that the valves are to be operated by electro-magnetic solenoids. Such solenoids already exist, as do the systems needed to control their operation precisely.

The new valve itself is likely to be made from well established materials with specific properties suited to the application. In my application, the three properties of most interest are low friction, high heat resistance and high magnetic susceptibility. The valve could be a composite construction to achieve these goals, but in any event suitable materials and the relevant technology relating to their design and use are to be found in existing applications.

Engine manufacturers will be able to produce more fuel efficient units that are simpler, smaller and lighter for a given power output. These units will consequently be cheaper to produce. Vehicle designers will be able to design vehicles around these units that deliver better fuel economy and which also have a lower centre of gravity.

The inventor is seeking to sell the design and all patent rights associated with it and would welcome enquiries from interested parties.

Patent publications:

Patent publications: No published information

No published informationAsk the inventor for a copy of the filed application

Asking price:

Make an offer

Make an offer

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2026-01-08 0:02:50, Patent Auction Time.

Great invention

Great invention