Home List your patent My account Help Support us

The New Building Block

[Category : - CONSTRUCTION HOME IMPROVEMENT]

[Viewed 523 times]

Abstract

A building block system wherein the lock-in system does not allow side movement once fixed. The blocks include channels and tunnels that accommodate wiring and pipes, including plumbing, electrical, heating/cooling, and more. The channels and tunnels can be used for air ventilation and air insulation and designed to eliminate moisture and mold. The block system can provide a final wall finish both externally and internally. The interlocking blocks are cost-effective and easier to build. The block system is suitable for domestic, commercial, and industrial, covering all building developments including home, office, factories, high-rise buildings, retaining walls and brickwork in all capacities above and below ground.

New Building Block Patent Number 2022200265

Description:

There are many factors that have contributed to the shortages of structured wood globally and it has become clear that alternatives will be required to make life sustainable on planet earth and it seems there are limited, economic, safe options available that will

stand the test of time in this ever- changing climate we are living in. Therefore, with that challenge in mind and fast forwarding to the future of building, the New Building Block is invented.

The exciting advantages that separate New Building Blocks apart from any other wall building materials are: Easy to work with and install and the average time for construction is 30% less using New Building Blocks. Due to the way the New Building Blocks lock into

one another, there is limited movement and therefore producing exacting results first time, every time.

The New Building Block has a clean edge finish and is designed to sit naturally in any section of a wall. When blocks are lined up, they lock into "precision" within the wall. In its completed form, the New Building Block features integrated tunnels and channels designed for mains installation, ventilation, and air insulation.

The central tunnels within the block are pre-built and spacious, facilitating ducted heating and cooling without the need for additional piping or ducting systems through ceilings and floors.

Smaller hollow sections within the block are designated for water pipes, electrical cabling, telephone wires, and other utilities.

Once installed, the New Building Blocks create a hollow wall structure, offering versatility for various applications such as heating, cooling, and cabling.

The size of the central tunnel is carefully selected to accommodate the requirements of heating or cooling units, with a minimum diameter of 150mm (approximately 5.91 inches) orlarger.

The joining sides of New Building Blocks are silicone or glued or filled in with a mortar or any other suitable joining products such as cement glue.

Additional rubber and foam seals are also recommended for alongside the wall block joins, and below legs of the block, to assist with shock absorption and expansion. Fine Mortar is

recommended as the ideal joining component. Wals with the New Building Blocks are designed to be straight, strong and weight bearing. The finish is suitable as is or a variety of

different finishes can be added to the wall such as rendering or plaster boards. The New Building Blocks can be made in different sizes, widths, heights, and lengths, depending on engineering structural design and calculations or placement of the proposed walls. The weight factor for safety has been considered, making the blocks easy to handle when building and transporting (internal/external walls). The New Building Block can also be

made from various natural raw materials such as sandstone, clay, crushed rocks, concrete, hemp, and recycled materials too. New Building Blocks offer a comprehensive solution for new construction projects, providing fire resistance and safeguarding internal wires and pipes. These blocks can be customized by cutting to fit corner sections or precasting to suit any external or internal corner configurations. Additionally, an internal wall

connecting section is available, although not depicted in the drawings provided. The incorporation of male and female grooves serves a dual purpose: acting as sealants and forming a locking system that enhances the strength and weatherproofing of the wall structure. It is advised to seal exposed groove sections to protect against weather elements such as rain and snow. This additional protection not only fortifies the mortar but also extends the structure's lifespan.

New Building Blocks are accompanied by a range of accessories to complete wall installations, including: •

END CAP blocks for providing a final finish to the end surface of the block if necessary

(Drawing 4).

• RETAINING WALL CAPPING STONE to furnish a final finish to the top and side of any wall

(Drawing 7).

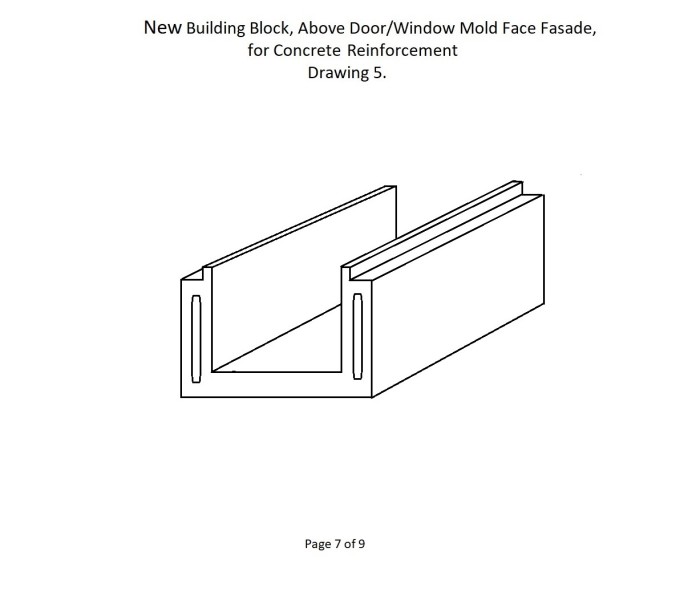

• ABOVE DOOR/WINDOW MOLD FACE FASADE (Drawing 5).

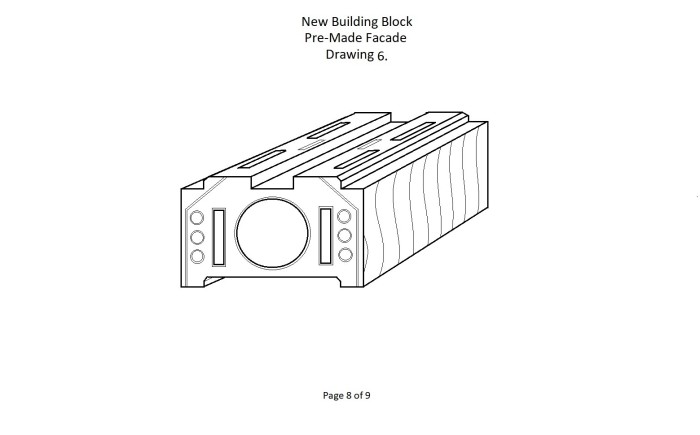

• PREFABRICATED EXTERNAL FACE FINISH (Drawing 6).

• WINDOW SEAL (Drawing 3).

Accessories also include a vent block section pre-made for easy mounting of all fittings.

Rubber or foam seals are optional for specific locations (e.g.: between blocks and below).

New building Block has a legs and Indentations section for mortar, specifically designed to isolate mortar from external and internal environment, to protect mortar from moisture, Mould, rainwater, wind, air flow and other. Additional plastic inserts are proposed between

Blocks horizontally for large central holes, to seal the centrallarge tunnel, hole, or a tube which are used only for rows where Heating and Cooling are run. The rest of Block rows in the wall do not require to be sealed around large central holes, and that allows air flow in those sections, which serves as additional ventilation for the Block and the entire wall structure.

Main features of a New Building Block are shown in Drawings and with detailed explanation attached.

New Building Block

Drawing Explanation

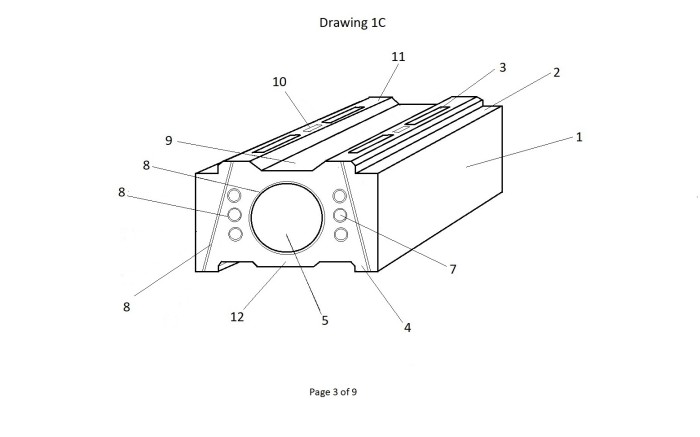

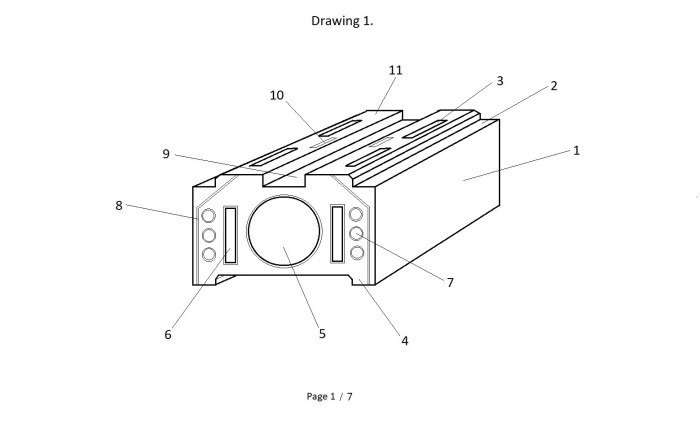

Drawing 1: Detail1: This depicts the external surface of the New Building Block, showcasing its versatility in design and pattern options. The surface can be left plain or adorned with various designs and patterns, instantly providing a final facade and finish to

the wall. In many cases, the use of New Building Blocks eliminates the need for additional rendering or finishing applications. Corner blocks are designed with two face sides and can feature the same finish as the rest of the wall or a different one, offering flexibility in design.

Detail 2: This section illustrates the leg rest of the New Building Block. These legs serve as support and can be glued or left unattached. Rubber pads or mats can be inserted horizontally between blocks, allowing the upper block to rest on rubber, which absorbs movements and enhances stability.

Detail 3: The vertical vent section is highlighted in this detail. It is designed for ventilation, air insulation, and the placement of mains and installations such as plumbing elements, pipes, cables, etc. This section connects with horizontal vents, establishing the ventilation system within each block and throughout the entire wall and structure.

Detail 4: This section illustrates the leg section of the New Building Block. The block is designed to rest on these side legs, in addition to the central section or middle of the block, which is typically glued but can vary depending on the application. This locking leg system ensures that the blocks are securely connected, providing precision, strength, easy installation, and stability. Minimal tolerances in movement in every direction allow for precise alignment and construction.

Drawing 1 (Detail 5): The central opening within the block is utilized for ducted heating and cooling, ventilation, and air insulation, particularly in sections of the wall where ducted heating and cooling are not applicable. Connections between blocks used for ducted heating and cooling are sealed, while in other sections of the wall/structure, they serve as ventilation passages. Cross joining sections with internal walls are also feasible, allowing ducted heating and cooling to be routed through internal walls.

Drawing 1 (Detail 6): This section depicts the ventilation

section/channel, running horizontally. These channels connect with vertical vents/channels, providing space for pipes and cables while ensuring good ventilation and air insulation. When blocks are

connected, these tubes create a clean and neat connection, facilitating the installation of pipes or cables.

Drawing 1 (Detail7): Side round tubes or sections are shown, which, when joined, create a tube profile. These tubes are ideal for running pipes or cables and are positioned close to the external edge for easier installation and accessibility.

Drawing 1 (Detail 8): This detail illustrates the joining section or groove, both internal and external (male/female) on either side of a block. When joined with another block, these grooves create a sealed connection, ensuring water and weatherproofing. It is

recommended to apply sealant and glue between these sections and joins for added protection.

Drawing 1 (Detail 9): Channeled central section on top of a New Building Block is depicted, where mortar or cement glue/other is placed. These sections also serve as additional glue spill rooms or expansion areas for sealant or mortar. Isolating these channels from the external face or surface of a block protects mortar from mold and moisture, thereby extending the lifespan of the wall and the entire structure.

Drawing 1 (Detail10): This detail shows the hand-holding section for easy handling, installation, and transportation of the block. Additional hand sections can be added as needed to balance and simplify block handling.

Drawing 1 (Detail 11): The upper section of a New Building Block is depicted, used for glue application and block weight support. It is also a strong section for weight absorption/load from upper New Building Blocks within the structural wall. Vertical vents on the surface of these block sections align and form straight vertical tubes or channels, suitable for plumbing and electrical applications and better ventilation of each block, the whole wall, and the entire structure.

Drawing 2: This drawing showcases the corner section/block, simplifying the erection of corner sections of the wall. Corner blocks have the same properties as straight New Building Blocks but with a different angle of 90 degrees connecting section, facilitating better fit and sealing at corners.

Drawings 3, 4, 5 & 7: These drawings illustrate accessories for wall construction with New Building Blocks, such as end cap blocks, retaining wall capping stones, above door/window mold face facades, and prefabricated external face finishes. These accessories contribute to a better slimline profile of the entire structure.

Drawing 6: This drawing demonstrates prefabricated facade options within the block, providing various finishes and designs for both internal and external surfaces. New Building Blocks are versatile and can be painted, sealed, rendered, or clad with different materials. Patterns on each block can match or differ, allowing for endless design possibilities internally and externally

New Building Block Claims

Claims are as follows:

Claim 1:

The new building block comprises a large central hole, which functions as an instant heating and cooling opening or as a tube for ducts when the blocks are longitudinally joined within the wall. The large central hole extends lengthwise along the block, with

protrusions and recesses around the hole, one of each at either end of the block, for precise block joining and sealing of sections between blocks. Additional silicone or glue is applicable for these joints, only for rows of blocks in a building selected for central heating and cooling purposes.

The central hole has a minimum diameter of around 150mm (approximately 5.91 inches) or larger to accommodate units for heating and cooling as per their specifications.

The new building block features three smaller horizontal round holes, which spread longitudinally on each side of the block, both inner and outer when viewed from the face of the block. These holes are stacked on top of each other on each side of the block and are designed to accommodate electrical conduits, cables, and plumbing pipes.

The building block includes square inner horizontal channels on both sides, visible from the block's face, for ventilation. Additionally, there are two vertical channels serving as ventilation for the block, intersecting with the horizontal square channels to form a unified

ventilation system on each side of the block/wall and each direction, visible from the block's face. The block's face is a small cross-section with all holes and features visible.

The new building block features two longitudinal exposed grooves on the upper middle section of the block, designed for precise block fitting.

The two sides of the block, viewed longitudinally from the block's face, serve as load bearing legs and the strongest sections of the block.

The new building block features a central top or upper recess/channel for mortar placement, spreading longitudinally on the block.

Additionally, the block further includes two side top recessed seats or steps designed for placing rubber pads or additional mortar between blocks; providing flexibility between blocks and accommodating each upper block.

The block further contains exposed upper longitudinal grooves which have beveled edges for simpler installation, allowing each block to slide into place.

The lower central part of the block is flat or convex where it encounters mortar.

The central mortar section is the top central recess longitudinally, which completely isolates the mortar from external and internal weather factors and environmental conditions.

The building block features long vertical recesses on its face for strip inserts.

Claim 2:

The building block of claim 1 further includes two longitudinally exposed upper grooves which extend upwards. Besides their function of providing locking of blocks, the exposed grooves also serve to prevent weather from entering the interior of the wall or any joined sections of the block longitudinally.

The exposed bottom legs of the block, when they overlap the exposed grooves from the block above, instantly seal the interior of each block, the wall, and the entire building.

These bottom exposed legs establish a locking position between each block vertically and provide structural reinforcement to the entire wall, preventing any sideways movement of blocks within the wall, both in and out of the building.

Claim 3:

The building block of claim 1 is further designed as a corner block, ensuring smooth and cohesive wall finishes around each wall corner. The corner block incorporates all the features of a straight new building block internally. Each section, channel, and hole/tube is curved 90 degrees on the corner block, aligning seamlessly with the corresponding sections of the straight new building block when joined.

This alignment of a straight blockwith the corner block also applies to all external sections, ensuring that the edges of the straight block match with the sections and edges of the corner block.

The internal and external surfaces of the corner block, when viewed from within the building or from outside, are smoothly finished and adopt any desired texture or finish consistent with the specifications of the straight block.

The corner block matches all features of a straight block.

Claim 4:

The new building block of claim 1 further includes a recessed section designed for easy hand handling on top of the upper exposed grooves longitudinally.

Claim 5:

The new building block of claim 1 is accompanied by proposed accessories designed to enhance the final aesthetic completion of specific wall sections. These accessories include: - Window seal - Above-door/window mold facade for concrete reinforcement - Retaining wall capping stone/element - End cap.

Claim 6:

The building block of claim 1 is a new building block which comes with several desirable internal and external block finishes, including texture, smooth finish, and optional cast color spectrum.

Claim 7:

The building block of claim 1 is further constructed with a variety of additional finishes cast into the block.

Claim 8:

The building block of claim 1 is further constructed from various materials, including recycled materials, concrete, clay, terracotta, hemp, special concretes, and can be made in any size in terms of length, width, and height.

Claim 9:

The building block of claim 1 is completely sealed all around when installed, resulting in a completely sealed wall and a completely sealed structure made of these blocks.

Claim 10:

The new building block of claim 1 further includes recessed sections on the face of the block for strip inserts. When blocks are joined together with strip inserts in place and sealed with silicone around the strip inserts on both sides, the combination of provided

features creates a completely sealed wall between blocks. Strip inserts can be made of rubber, steel, plastic, wood, or cement, and they must be weatherproof.

Patent publications:

Patent publications:No publication

Asking price:

Make an offer

Make an offer

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2025-12-31 2:48:37, Patent Auction Time.

Great invention

Great invention