Home List your patent My account Help Support us

Rethinking Heat Exchanger: Efficiency and Sustainability

[Category : - MECHANICAL ENGINEERING- RENEWABLE ENERGY]

[Viewed 441 times]

With ongoing discussions about climate targets, energy savings, and rising material costs, the efficiency of heat exchangers in air conditioning systems and heat pumps is more critical than ever. The traditional fin-tube heat exchanger design has seen little change over the years, with optimizations mainly focusing on flow velocity and geometry—often at the cost of increased material and energy consumption.

Our invention demonstrates that even small adjustments in the arrangement of fins and tubes can have a significant positive impact on efficiency. The patented technology enables a substantial reduction in energy and material consumption, leading to cost savings for both manufacturers and consumers. Furthermore, this innovation offers additional benefits, including reduced space requirements, lower noise levels, and faster heating times.

In practical applications, such as a heat exchanger with dimensions of 28 × 20 × 14 cm, energy savings of up to 57% or material savings (fins/tubes) of up to 39% can be achieved.

These innovations were filed with the German Patent and Trademark Office (DPMA) in 2012 and granted in 2022. They have gained international recognition and were awarded a bronze medal at the iENA 2012 in Nuremberg.

The impact of these innovations extends beyond individual devices. For consumers, this means lower energy consumption, shorter heating times, and reduced noise levels. Manufacturers benefit from lower material and transportation costs, enhancing their competitiveness. On a governmental level, this technology helps prevent power grid overloads and contributes significantly to achieving climate goals.

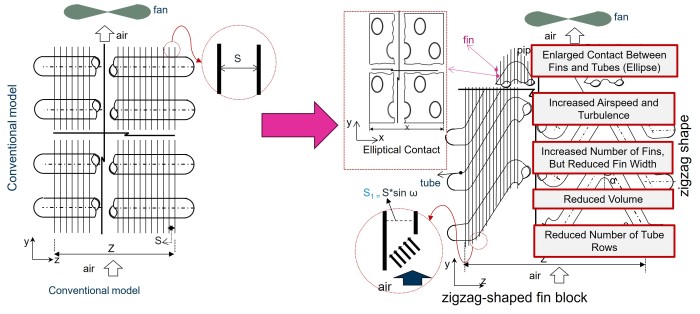

This patent introduces an innovative technology for optimizing heat transfer in heat exchangers, utilizing a design referred to as the "zigzag shape." The zigzag heat exchanger is achieved by tilting the tubes while keeping the fins vertically aligned, resulting in a distinct zigzag formation. The main result is to increase the areas of the heat exchanger where heat transfer is most efficient, particularly on the air inlet side, while minimizing the less effective areas.

Key advantages of this innovative arrangement include:

• Elliptical contact between fins and tubes, improving heat transfer efficiency

• Airflow no longer moves parallel to the fins, increasing turbulence for better performance

• Larger air inlet areas compared to the spaces between fins, leading to higher air velocity

• More fins can be accommodated within the fin block, reducing fin height and the number of tube rows, further enhancing efficiency

This optimized design significantly improves heat transfer efficiency, offering a resource-efficient and cost-effective solution for heat exchangers across various applications.

Financial information

Goals:

- Licensing

- Sale

- contribution to climate protection

Asking price:

Make an offer

Make an offer

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2025-11-26 3:40:36, Patent Auction Time.

Patent publications:

Patent publications: DE 102012007063

DE 102012007063 Great invention

Great invention