Home List your patent My account Help Support us

INJECTION AND MIXING OF CHEMICALS INTO A FLUID DELIVERY SYSTEM

[Category : - MECHANICAL ENGINEERING- Construction Processes & Equipment- Agriculture]

[Viewed 613 times]

Same can be true for other applications. In fertilizer injection, without mixing, the fertilizer concentrate will get pulled through the pipeline and create uneven coverage or application rate. Some areas will receive more fertilizer concentrate than others.

Any application where a homogeneous mixture is desired might be able to be improved with this process, eliminating the need for electrical components, and more complicated delivery systems. Ideally on a commercial irrigation application this could be a simple unit to install, and servicing would be highly cost effective. Imagine having a lawn service company like true green, except the labor time and knowledge/training required would be significantly reduced and only require a technician the time it takes to fill a small holding tank with fertilizer. Business opportunities abound.

Since this is a utility patent, as long as the injection and mixing functions are included in design and build, the patent should protect alterations to specifics.

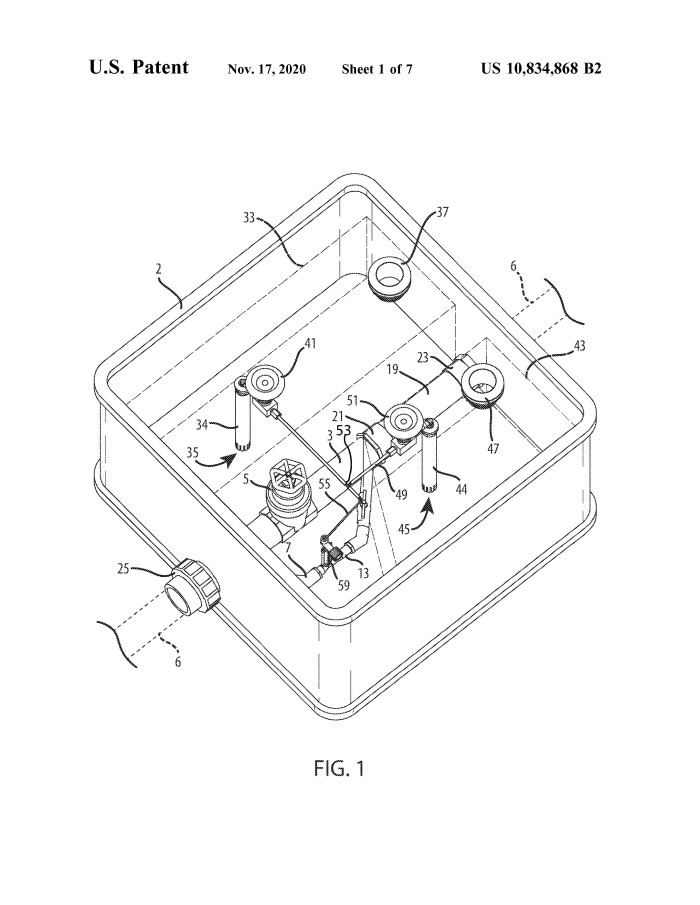

A fluid mixing and delivery system, e.g., for use in chemical injection of irrigation systems or wash-down stations, has a main fluid conduit with an inlet and an outlet, a bypass conduit with an inlet and an outlet, a venturi, a chemical storage tank, and a static mixer. The bypass conduit inlet connects to the main fluid conduit downstream of the main fluid conduit inlet and the bypass section outlet connects to the main fluid conduit upstream of the main fluid conduit outlet. The venturi is located in-line with the bypass conduit between the bypass conduit inlet and the bypass conduit outlet. The chemical storage tank is fluidly connected to an individual supply line, which fluidly connects to the venturi. The static mixer is located in-line with the main fluid conduit between the bypass conduit outlet and the main fluid conduit outlet.

Financial information

have you been watching the news on the hurricanes? All of the flooding has caused massive contamination of drinking water lines. After hurricanes gastrointestinal illnesses spike! You know why? because sewage and storm water enters into the public drinking water from water main breaks when roads wash out, line breaks from mudslides or tornadoes, all of the fun stuff that comes from those disasters. So think about how they will they make the lines safe to serve drinking water again? They need to be disinfected with high concentrations of chlorinated water. This device can inject a slurry of highly chlorinated water into a flow and disinfect pipelines throughout the those effected cities. Once the chlorine has contacted the surface for enough time, the chlorine can be dechlorinated using the same device. Water flushed through, and now the water is safe to drink again. Im telling yall, the possibilities of this are endless. More than a 1 trick pony.

According to Grandview Research, The U.S. water and wastewater treatment equipment market generated a revenue of USD 7.1 billion in 2023 and is expected to reach USD 8.6 billion by 2030.

According to Statista, The global fertilizer market amounted to more than 193 billion U.S. dollars in 2021, an increase of roughly 12 percent in comparison with the previous year. It is forecast that the fertilizer market will surpass 240 billion U.S. dollars by 2030.

Get a piece of that pie, not to mention any other industry that could utilize the function of this design for their processes. Potential is huge and functionality and application crosses numerous markets.

Asking price:

Make an offer

Make an offer

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2026-01-09 18:34:11, Patent Auction Time.

Patent publications:

Patent publications: US 10834868

US 10834868 Great invention

Great invention