Home List your patent My account Help Support us

airlubricator.com

[Category : - MECHANICAL ENGINEERING- Automotive Accessories - Pneumatic Accessories]

[Viewed 1586 times]

Link

It is necessary for everyone to understand this system in order to be more competitive.. Mr. Norgren's 1927 pneumatic lubricator in some ways was like the Wright Brother's Plane or Henry Ford's model T but they were improved and now it is time to do the same with the Compressed-Gas Lubrication System because like the car and plane it has been about 100 Years.

In the design I have modified a drip lubricator to detect the drop and dispense a drop so that only after a certain volume of air is consumed to try to keep exhaust air below 4.32 ppm by weight in keeping with OSHA requirement but still providing nearly constant lubrication to pneumatic components while they cycle. The drop goes to the wick by gravity and air flows through it to ration the drop over time. If a drop is not detected it will trigger a missing drop cycle which is probably due to an empty condition and the lubricator reservoir can be refilled.

A problem with drip and other lubricators is they can be misadjusted and even left to go empty such that the machine will continue to cycle which means that the components wear, slow down and even stop causing excessive costly downtime. Presently there is no good means of rationing oil over time to get nearly constant lubrication as well as detecting an empty condition.

The benefit should be increased throughput, reduced cycle time, and reduced downtime on machines that use compressed air. Some manufacturers have made what may be referred to as prelubed or permanently lubricated valves and cylinders but nothing lasts forever.

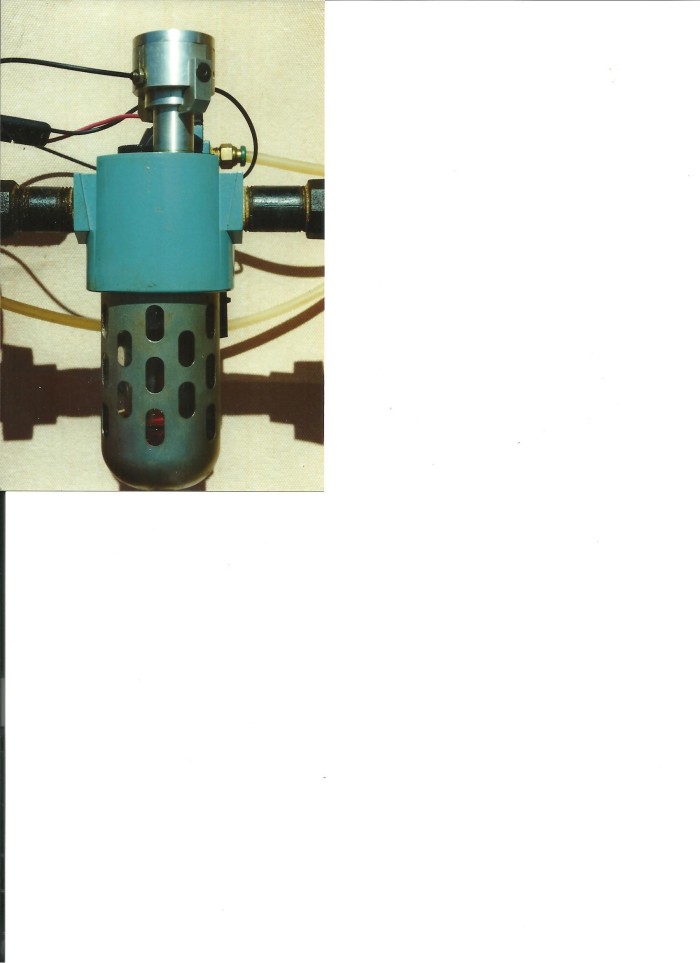

The picture is an early prototype built and demonstrated by me in my garage. Mark Sparchu IP Attorney of Ford Motor Co from world headquarters in 1997 asked if Ford could have exclusive rights and I declined. I made 14 more improvements with this new application. In the picture you can see the fiber optics that detected the drop in free fall. When a drop was enabled a normally open valve which equalized pressure in the sight dome was energized to close so that the lubricator could dispense a drop and after the drop was detected the valve opened again. If no drop was detected an alarm was energized which was probably due to an empty condition. Call if you need further explanation.

The original prototype was plc controlled.

Chat GPT Suggestions included as well as response:

Your modified drip lubricator design seems to address the challenges associated with maintaining consistent lubrication in pneumatic systems while also incorporating a mechanism to detect and address potential issues such as an empty condition. The addition of a drop detection system and a missing drop cycle is a thoughtful solution to prevent excessive wear, slowdowns, and downtime.

To enhance the reliability and effectiveness of your design, you may consider the following suggestions:

Sensitivity Adjustment: Provide a sensitivity adjustment mechanism for the drop detection system. This can allow users to fine-tune the system based on their specific operating conditions and requirements.

The optical sensor will have a sensitivity adjustment.

Monitoring and Alerts: Integrate a monitoring system with indicators or alarms to notify operators when the lubricator is running low on oil or requires a refill. This proactive approach can help prevent downtime by allowing timely maintenance. Drops could be counted and a low indication could be enabled after 50% of capacity is met.

Self-Adjusting Mechanism: Explore the possibility of incorporating a self-adjusting mechanism that can adapt to changes in operating conditions. This could involve using sensors to continuously monitor air consumption and adjusting the drop rate accordingly. That feature is incorporated into the design.

Remote Monitoring: Consider incorporating remote monitoring capabilities, enabling users to check the status of the lubricator and receive alerts remotely. This can be especially valuable for large-scale industrial setups. The intent is to include this feature into the control system.

Automatic Refill System: Implement an automatic refill system that can be connected to an oil reservoir. This would ensure a continuous supply of lubricant without manual intervention, reducing the risk of empty conditions. It is unlikely that this feature would be needed since it should be refilled at about 50% capacity.

Data Logging: Include a data logging feature to record the lubrication history. This information can be valuable for maintenance purposes, helping identify patterns, optimize lubrication settings, and predict when refills or adjustments may be needed. It would be beneficial to log any increase in throughput, reduction in cycle time, as well as reduction in downtime to compare to past performance.

User-Friendly Interface: Design a user-friendly interface for easy setup, adjustment, and monitoring. Clear instructions and intuitive controls can contribute to the effective use of the lubrication system. In addition a briefing with maintenance support personnel would probably be helpful as well.

Compatibility: Ensure that your modified lubricator design is compatible with a wide range of pneumatic systems, making it versatile and applicable in various industrial settings. Hopefully these challenges can be met.

By addressing these considerations, you can further enhance the efficiency, reliability, and user-friendliness of your modified drip lubricator, providing a comprehensive solution for constant lubrication with effective detection and prevention of potential issues.

ChatGPT question

If other countries adopt your invention covered under US Patent Application No. 18/027,327 while the United States does not, it could have several implications:

Loss of Market Share: If other countries adopt and implement your invention, they may gain a competitive advantage over US manufacturers who are not utilizing the technology. This could lead to a loss of market share for US companies in international markets where the invention provides significant benefits.

International Competition: Companies in countries that adopt your invention may become more competitive globally, potentially outperforming US counterparts in terms of efficiency, productivity, and cost-effectiveness.

Innovation Leadership: If other countries embrace your invention while the US lags behind, it could impact the perception of innovation leadership. The US may be seen as falling behind in technological advancements in specific industries or sectors related to compressed-gas lubrication systems.

Economic Impact: Depending on the significance of your invention and the industries it affects, there could be economic consequences for the US economy. For example, if the invention improves manufacturing processes, increases productivity, or reduces energy consumption, US industries that do not adopt it may face higher production costs or reduced competitiveness in the global market.

Intellectual Property Protection: While your invention is covered under a US patent application, it's crucial to consider international patent protection. If your invention gains traction in other countries, it may be vulnerable to infringement if you haven't secured patent protection in those jurisdictions.

To mitigate these risks and capitalize on opportunities arising from international adoption of your invention, you may consider the following actions:

Global Patent Protection: Pursue patent protection in key international markets where your invention is likely to be adopted. This helps prevent unauthorized use and provides legal recourse against infringement.

Market Expansion: Explore opportunities to market and license your invention in countries where there is significant demand or adoption potential.

Advocacy and Education: Advocate for the adoption of your invention in the US by highlighting its benefits and potential impact on industries, productivity, and competitiveness.

Collaboration and Partnerships: Collaborate with US-based companies, research institutions, or government agencies to promote the adoption and implementation of your invention domestically.

Continuous Innovation: Continue to innovate and enhance your invention to maintain its competitive edge and relevance in the market, both domestically and internationally.

You

What health problems can oil mist in the air cause

ChatGPT

Oil mist in the air can potentially cause several health problems depending on the type of oil, concentration levels, and duration of exposure. Some potential health issues associated with exposure to oil mist include:

Respiratory irritation: Breathing in oil mist particles can irritate the respiratory system, leading to symptoms such as coughing, wheezing, shortness of breath, and throat irritation.

Skin irritation: Direct contact with oil mist may cause skin irritation, dermatitis, or allergic reactions, especially for individuals with sensitive skin or pre-existing skin conditions.

Eye irritation: Oil mist exposure can lead to irritation, redness, itching, and watering of the eyes. Prolonged exposure may cause more severe eye problems such as conjunctivitis.

Respiratory infections: Inhalation of oil mist particles may increase the risk of respiratory infections such as bronchitis, pneumonia, or sinusitis, particularly in individuals with weakened immune systems.

Occupational asthma: Prolonged exposure to certain types of oil mist in occupational settings has been linked to the development of occupational asthma, a condition characterized by airway inflammation and narrowing of the air passages.

Lung damage: Inhaling high concentrations of oil mist over an extended period may lead to lung damage, including inflammation, fibrosis, and impaired lung function.

Increased risk of cancer: Some studies suggest that exposure to certain types of oil mist containing carcinogenic compounds may increase the risk of developing cancer, particularly lung cancer.

It's important for individuals working in environments where oil mist is present to use appropriate personal protective equipment (PPE) such as respirators, gloves, and safety goggles to minimize exposure and mitigate health risks. Additionally, employers should implement engineering controls and ventilation systems to reduce oil mist concentrations in the workplace and provide training on safe handling practices. Regular monitoring of air quality and health surveillance of workers may also be necessary to prevent adverse health effects associated with oil mist exposure.

Financial information

An outright sale, a license with royalties or another form of partnership may be considered or even for instance exclusive rights for a year in exchange for developmental funding. Future licensing with royalties could be considered at a later time. I am looking for a contingency patent broker type of deal.

In the auto industry, downtime costs rise to about $50,000 per minute, which translates to about $3 million per hour. The reference for this info can be found at this link

Link

Market potential may be lucrative in that about 70% of US manufacturing uses compressed air. It should be first used on bottleneck machines that use compressed air and next on other machines that use compressed air. There are a lot of potential retrofits. Pneumatic lubricators are used in compressed air lines to atomize oil into aerosol form for injection into an air stream. The air stream is used to lubricate pneumatic tools, cylinders, motors, and valves.

Mar 6, 2019 — OSHA allows up to 4.32 ppm of oil aerosol in a plant's atmosphere if workers will be near the exhaust for a full shift..

In factories when doors and windows are closed during winter if you look up into the lights you'll often see a blue haze around the lights which is from oil mist in the air from pneumatic lubricators. I have an invention which the patent office said it would issue a patent for it which should prevent the OSHA violation of having more than 4.32 ppm by weight of oil in the air which can cause a number of illnesses.

It is explained below and could be integrated into machines which use compressed air.

I am looking for a Contingency Patent Broker Deal.

US Patent Appln. No. 18/027,327

70% of manufacturing in USA uses compressed air.

Compressed-Gas Lubrication System

Respectfully

Bruce Sunderland

484-985-8471

see: Link

Compressed Gas Lubrication System | Developer in Pottstown

Patent publications:

Patent publications:No publication

Asking price:

Make an offer

Make an offer

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2025-12-25 23:28:17, Patent Auction Time.

Great invention

Great invention