Home List your patent My account Help Support us

Single Use Apparatus for pilot & production Chromatography columns

[Category : - MECHANICAL ENGINEERING- OTHER- DESIGN PATENTS]

[Viewed 849 times]

LUCID is a chromatography system with only 3 silicone-moulded tubing manifolds certified USP VI capable of 10 to 1000 L/min.

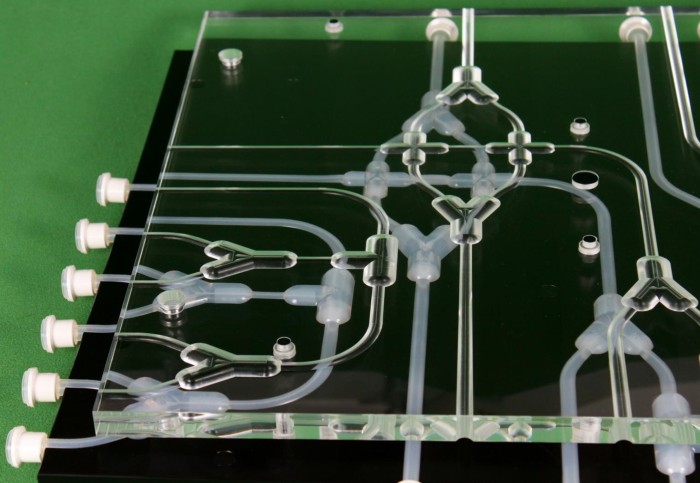

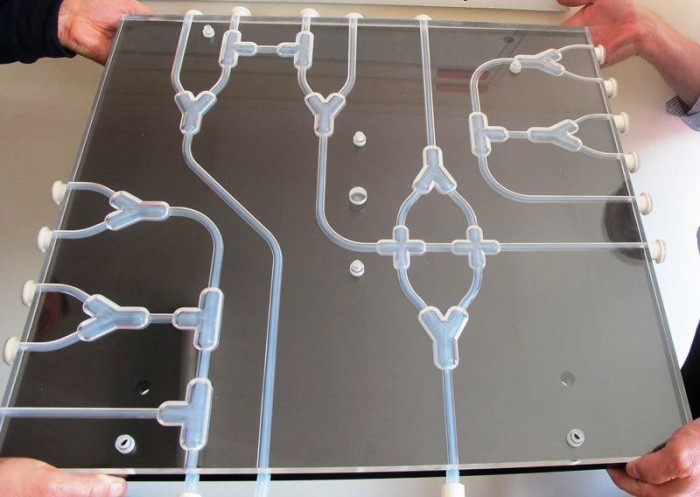

We have developed a network of Pt-cured silicone tubing or a nuclear grade material with valves mimicking the artery clamps but automated (or manual) as one single continuous manifold with neither internal triclamp nor seals nor similar joints, with completely non-invasive pinch valves.

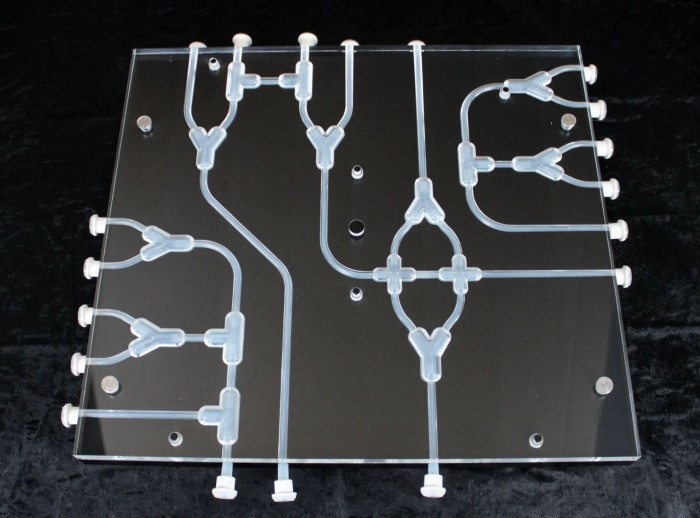

This network of Pt-cured silicone tubing sits between two channels, one side acrylic, for transparency, the back side for mechanical strength on which the actuators are mounted.

Thus the tubing becomes a ‘liner’ according to PED and ASME. But note neither the acrylic nor the acetal is wetted, only the tubing.

These two plates swing together to encapsulate the tubing network thereby becoming the pressure envelope. This prevents bursting of the tube even when it is subject to internal pressures substantially higher that its usual rated pressure, of 0.5 bar!

Benefits

• Complete system tubing set is discarded and renewed within 10 minutes removing the need for long CIP cycles and large volumes of NaOH solution. Our competitor’s skids take a day and use Jubilee clips and 10’s of tubing pieces!

• LUCID solves difficult tubing exchange, gives higher pressure and thus higher flow so 1 LUCID will run columns from 20-mm ID to 1-metre diameter.

• 150g (1 billion doses) of EPO requires 10 million litres of sterile and water for injection. LUCID requires 10 column volumes e.g. 250-L for a 40-L column.

• Unique pressure envelope allows the preferred Pt-cured silicone tubing to be used up to MAWP of 15 bar

• No joints, no complex valves, only pinch on the silicone tubing open & closed by pneumatic bar onto the silicone (peristaltic) tubing.

• No tubing or valves, seals clearance tests.

• Optimised column performance due to minimal or zero dead space with no hold-up volumes.

• Plastic 100% recyclable process train.

• USP Class VI, EP 3.1.9, FDA, and ISO criteria

• Reduced cleaning costs; cleaning validation; capital equipment costs.

We see our system being used in the following applications

• Chromatography skid alternative

• Filtration and ultrafiltration skid alternative

• Sterile transfers

• Bioreactor process systems

• Contract manufacturing

• Nuclear waste transfers

Financial information

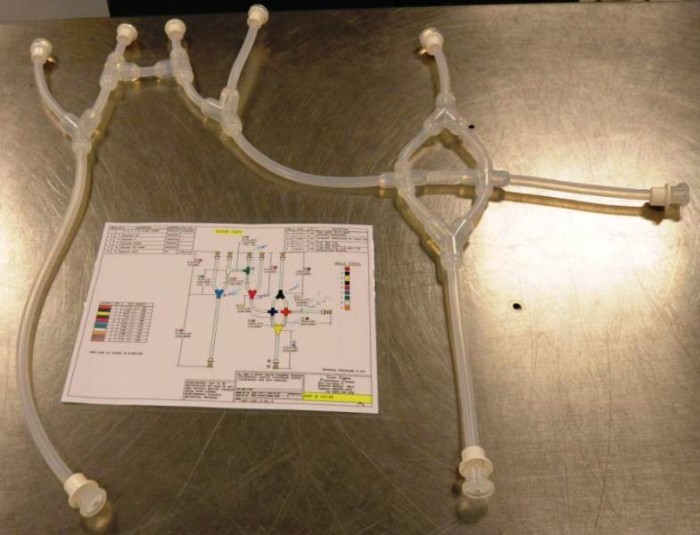

Biotechflow was launched in 2010 when we started to design a single use skid for chromatography called ‘LUCID’. It is only 3 silicone-moulded tubing manifolds, 10-mm bore with 6, 5 and 8 terminations in certified USP VI capable of 10 to 1000 L/min. The 3-manifolds are in the ‘standard chrom skid P&ID. BUT requires NO seal, no triclamps except at terminations. The mobile phase is directed by pinch valves.

The 3 networks are single individual moldings which sits between two plates 20-mm thick with channels to accept the tubing easily, one side acrylic, for transparency, the back side, acetal for mechanical strength. Thus the tubing becomes a ‘liner’ according to PED and ASME. But note neither the acrylic nor the acetal is wetted, only the tubing.

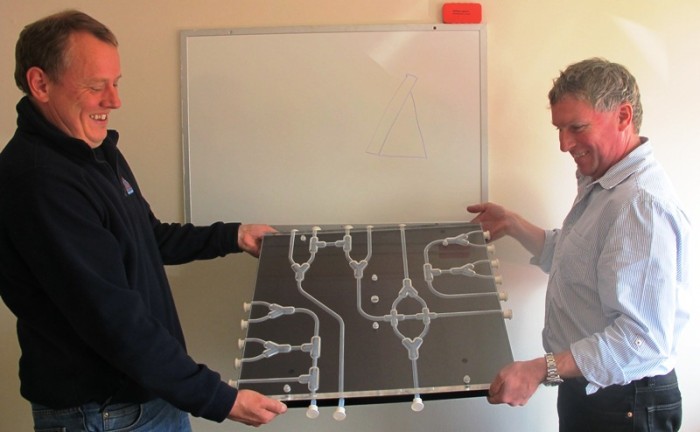

These two plates swing together to encapsulate the tubing network thereby becoming the pressure envelope. It is about the size of a 32-inch flat screen television and can be wall mounted. This prevents bursting of the tube – the pressure envelope being the two plates, so the wall thickness is about 12-mm. LUCID can be used for 50-mm to 1,000 mm diameter chromatography columns with the one standard sized unit. Applications include biotherapeutics, hazardous wastes including nuclear waste.

We applied for and were granted patents in 11 jurisdictions mainly Europe & USA, please follow links: EP2699340A1;. Mainly advantage over Sartorius, Cytiva and the new Thermo-Fisher (HyPeak) is that the max operating pressure (PED) is 8-bar, the size is considerably smaller than competitors, and of wall mounted takes no floor space. It takes 10-minutes to renew the 3-manifolds. There are no ‘clips, hose barbs, no non-swept areas.

We have been designing and building Expanded Bed Adsorption (EBA) columns at pilot to production scale,

We’ve been selling our standard 300-mm ID (70-litre) and 600-mm ID (280-litre) EBA columns for 12-years.

We have sold these production EBA columns on 4 continents for mAb’s, vaccines, therapeutic polypeptides - all isolated directly from 2,000-5,000-L biomass, no centrifugation, no filtration, 1/3 cost, time, space versus conventional methods. All our columns are sold with the FAT, IQ, OQ, USP VI and all FDA/EMA validation requirements for human injectables.

We have patented our designs (now our standard columns) in 11 jurisdictions – see attached. Our core patent was granted on 31/03/21.

We have distributers in Israel, USA, Europe and South America.

BTF-EBA uses upward flow to expand the chromatography media. Unclarified biomass is injected upflow directly from the bioreactor into our EBA column. The target molecule, or cells are isolated in capture or flow-through mode.

• To give you a quick overview please watch a 1-minute movie showing the savings in CAPEX and OPEX from using EBA

You Tube Link: Link

REASON FOR SELLING LUCID PATENT: We want to concentrate globally on our EBA columns.

Asking price:

360,000 USD

360,000 USD

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2025-11-26 5:12:57, Patent Auction Time.

Patent publications:

Patent publications: EP 2699340

EP 2699340 Great invention

Great invention