Home List your patent My account Help Support us

Automatic transmission.

[Category : - Motors]

[Viewed 1111 times]

Link

The creation of an automatic transmission (AT) with a constant module (n) and variable gear ratio (i) is the dream of every automaker such as VAG, Toyota, Renault - Nissan - Mitsubishi, General Motors and Hyundai - Kia.

The theory of mechanisms denies the possibility of the existence of a gear mechanism with a variable gear ratio (i) with constant gearing of gears.

Car gearbox designers are trying to develop fixed modulus (n) and variable ratio (i) automatic transmissions

I will talk about the design of variable ratio gears (i) and constant modulus (n).

The variable gear ratio of the gear train (i) is necessary to change the angular speed of rotation of the wheels (w) from 0 to a given value.

A permanent gear module (n) is selected to be able to manufacture a gear or wheel in metal.

------------------------------------------------------------------------

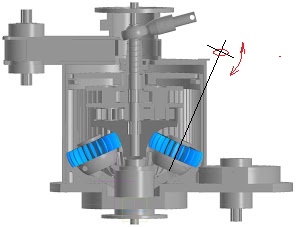

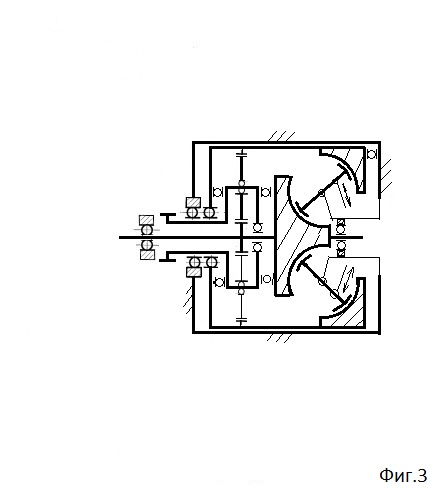

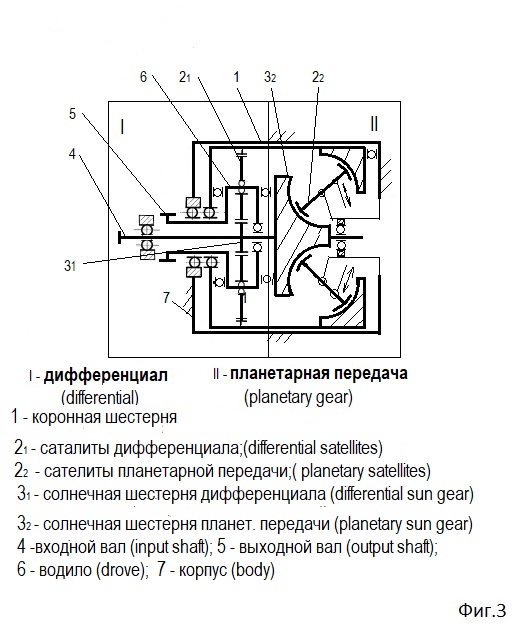

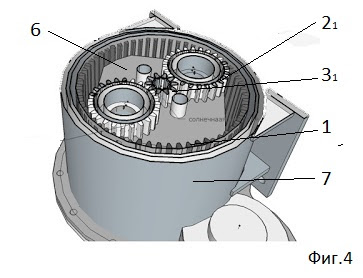

FIG. 1 Shows a general view of the variator. Figure 2 shows a longitudinal section. Figure 3 shows a structural diagram. Figure 4 shows a cross section.

The gear variator consists of a differential I and a planetary gear II, with one ring gear 1. satellites: differential -21, planetary gear -22, differential sun gear - 31 and sun gear 32, planetary gear II .. There is also an input shaft 4 , output shaft 5, planet carrier 6 of satellites 21, body 7 (shell). Differential I has two degrees of freedom. Planetary gear II has three degrees of freedom. The gear ratio (i1), differential I, in my version, is i1 = 6. Gear ratio (i2) of planetary gear II, adjustable and changes in the interval, i2 = 1 -: - 1/6. This means that when the angular speed (w) on the input shaft 4 is 6000 rpm, the revolutions (w) of the output shaft 5 can vary w = 0 -: - 1000 rpm. both in the forward motion and in the backward motion.

The change in the angular velocity (W1) on the satellites 21 of the differential I, which is connected by means of the carrier 6 with the output shaft 5, transmitting the moment of force (M) to the wheels, occurs due to the change in the gear ratio (i2) of the planetary gear II, at a constant value of the modulus (m ). In my version, the module is m = 4. The gear ratio (i) of the continuously variable transmission (gear variator) is, i = i1 x i2, At i2 = 1/6, - i = 6x1 / 6 = 1. The wheels don't turn. For i2 = 1, - i = 6x1 = 6. The wheels rotate at maximum speed.

------------------------------------------------------------------------

Changing the speed of the vehicle is carried out due to the relationship, differential I and planetary gear II, forming a single mechanism. In planetary gear II, a smooth change in the gear ratio (i2) of the gear wheels is provided. If the reduction ratio (i2) of planetary gear II is compared to the overdrive ratio (i1) of differential I, the carrier 6 and the output shaft 5 are stationary and the sun gears (31) and (32) rotate. As soon as the gear ratios of differential I and planetary gear II go out of balance, ring gear 1 starts to increase its speed. Since the sun gears (31) and (32) are paired and rotate at the same speed, and ring gear 1 starts to spin faster, then the carrier 6 with the satellites of the differential I also begin to spin faster.

An original solution was found for connecting planetary gear II satellites with a sun gear and a ring gear. Regardless of the fact that the surfaces of the sun gear and ring gear have a toroidal shape, their contact patch has the same shape as if the teeth were connected in a spur gear train. I will prove it. I have developed a 3D model of the device in the drawing program Compass.

Financial information

Unlike an automatic transmission with a V-belt transmission, this device will save 30% of fuel, it does not need expensive oil, it will heat up less and will not slip in traffic jams in front of traffic lights.

Patent publications:

Patent publications:No publication

Asking price:

Above 1 million USD

Above 1 million USD

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2026-01-09 20:26:20, Patent Auction Time.

Great invention

Great invention