Home List your patent My account Help Support us

CRYSTAL SLEEVE Shrink Tubing (Product and Process)

[Category : - MECHANICAL ENGINEERING- OTHER- CHEMISTRY]

[Viewed 1480 times]

This technological process has been developed over 24 years of R&D.

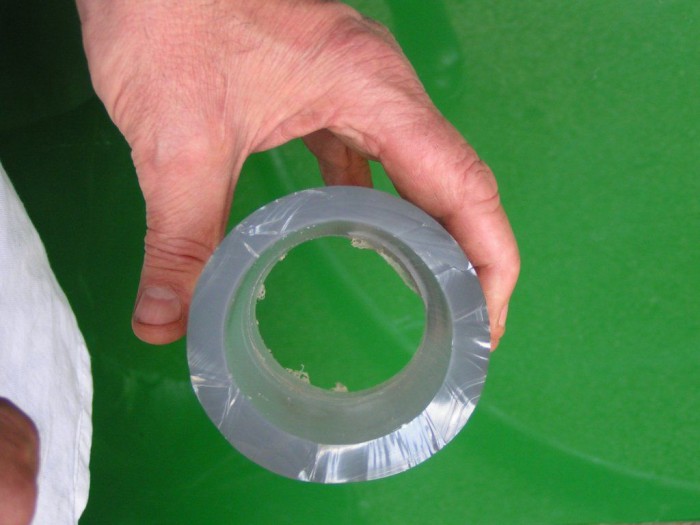

The invention relates to a method and a device for the homogeneous extension of a heat-shrinkable sheath (10). The method comprises the steps of: supplying a parison (2) made of polymer material, having an initial diameter (Di); Heating the parison (2) by means of a fluid; Inflating a portion of parison (2) to stretch said portion and increase its diameter; Sealing of the inflated parison portion (2) to create a gas bubble (20), having a nominal diameter, inside the parison (2); Scrolling the parison (2) around the gas bubble (20) to stretch the entire parison (2); Cooling of the stretched parison portion (2) to maintain the nominal diameter (Dn);

This technological process was developed during 24 years of R&D, to respond to an expressed need of gas companies to overprotect gas cylinders with a plastic coating, with a view to reducing maintenance operations and guaranteeing the legibility of the characteristics and references of the bottles.

Main Features:

- Temperature -55 ° C to + 110 ° C

- UV resistance, corrosion, moisture, chemicals and flame

- Good electrical insulator

- damping coefficient to major shocks

- Recyclable through the channels up

- Intelligent Material At Macromolecular Level

Descriptive:

For what purpose?

Overprotection device to act as a second skin and to adapt to any type of support, under extreme or non-extreme conditions. Enabling all kinds of devices, structures, dangerous elements to be secured. (Nuclear, radioactive, pollutants...)

Origins of innovation?

This technological process is a response to a need expressed by a consortium of many international companies active in the heavy industry sector. Some actors in the gas sector_ in the broadest sense expressed a need to create a direct overprotection for their bottles.

What is the invention made of?

It consists of intelligent raw materials, the processing machine, and all the 24-year R&D know-how required for production.

The raw material?

The innovation of this formula acts directly on the macromolecular chains of matter. This innovation allows macromolecular chains to assemble and "break" to find an optimal molecular arrangement (stretching or, retracting): Intelligent Matter At The Macromolecular Level.

The machine?

A device designed to be easily applicable to diameter, length required, etc, to ensure a continuous production. Easily transportable to optimize transport and storage costs (warehouse, field, etc.)

Who is it meant for?

- The device according to innovation is partly aimed at

- The nuclear sectors (production, storage, waste management...)

- Building infrastructure

- Oil and gas

- Drilling

- New energies

- Etc.

Environmental

The material has been designed to be recyclable through existing channels. As well as the products used during processing, they were considered to be reusable and non-polluting. As well as the maintenance of the various mechanical parts.

Financial information

This technological process was developed during 24 years of R&D, to respond to an expressed need of gas companies to overprotect gas cylinders with a plastic coating, with a view to reducing maintenance operations and guaranteeing the legibility of the characteristics and references of the bottles.

However, this process is not limited to this single field of application. The innovation and technological process can be applied directly in different sectors:

? Nuclear (production, storage, waste management, etc.)

? Building infrastructure

? Oil and gas

? Drilling

? New energies

? Etc.

This CRYSTAL SLEEVE sheath protects, insulates, follows the forms of the product requiring protection.

Examples of applications:

? Overprotection of insulation sheaths in areas at high risk of degradation.

? Overprotection of connection joints in petroleum exploration

? Overprotection of underwater and underwater pipes

? For toxic material storage containers

? Adaptable and customizable according to the application requested

? Reinforcement of the various elements on offshore platforms

? Safety when storing radioactive waste

? Aeronautical application

? Other...

Industry analysis

? Is the industry seasonal? Does the majority of business operations take place during only part of the year?

No, nuclear, infrastructure, and industrial operations occur year round and are robust to fluctuations in climate. With industry stability, the demand for this product would only depend on the wear, and needed protection, of an implement.

? Is the industry subject to certain regulations? What are they?

There are regulations to the toxicity of the material and its reaction with its respective environment. Aquatic operations especially would require toxicity impact studies near their implementation in accordance with federal and local laws. There would need to be routine checks on applications to check for leaks and damage, as would be done for any other toxic storage and pipeline equipment.

? Is the industry sensitive to economic fluctuations?

No, industrial and storage applications are robust against small economic fluctuations, especially when they are a general necessity product and are applicable to multiple

industrial needs.

? Is the industry growing? What are the technological changes ongoing in the industry?

As large scale manufacturing grows, the need to have safe and reliable transportation and storage methods also grows. Modern industries are becoming more globalized and materials require greater rates of safe transport and storage. There are upcoming needs for safe transport and storage of nuclear waste as there is for oil equipment in environmentally sensitive areas. That being said, the increasing prevalence of power

industries like solar and wind require less transport and storage of liquid materials, which would have less of a need for this product.

Market analysis

? Can you define your market clearly? Who are your potential customers in the market?

Yes, markets that would use a product like this would include international pipeline companies, infrastructure groups, and power industries (oil, nuclear, etc.). These companies could manufacture the PVC sleeves themselves, or outsource the manufacturing to a material manufacturer. Potential customers include ExxonMobil, BP, Lukoil, Chevron, Shell, Kinder Morgan, Enel, Tepco, and General Electric. This is a general purpose piece of equipment that can be licensed to many industries at a time.

? What is the size of the market in terms of number of potential customers and revenue? How fast is the market growing?

The global advanced energy market surpassed 1.4 trillion USD in 2016, a 7% increase compared to an updated 2015 total of 1.3 trillion USD. This includes both fuel and electricity production. The global nuclear power plant and equipment market accounted for 36.484 billion USD in 2017 and is anticipated to generate revenue of 49.038 billion USD by 2025, growing at a CAGR of 3.7% from 2018 to 2025

Asking price:

Make an offer

Make an offer

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2025-11-27 8:28:34, Patent Auction Time.

Patent publications:

Patent publications: FR 1456152

FR 1456152 Great invention

Great invention