Home List your patent My account Help Support us

Medical Delivery Device:

[Category : - HEALTH]

[Viewed 1425 times]

Technology for Medical, Beverages, Food, Personal Care and Chemical Products, ,

For more information go to: Link

Overview:

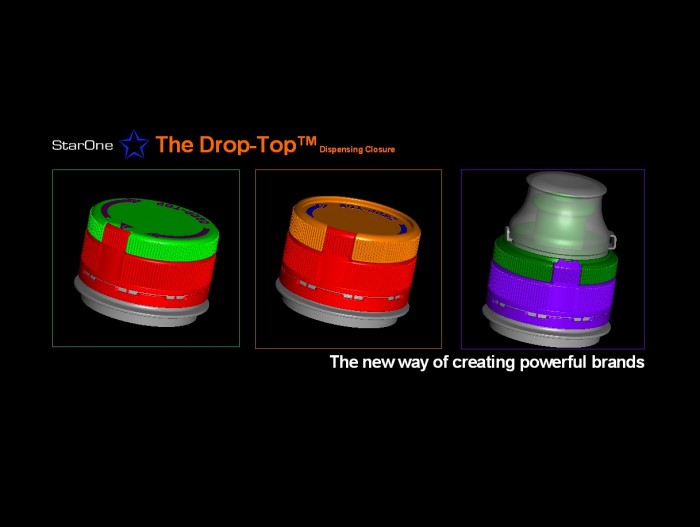

This revolutionary technology provides total solutions for packaging a vast array of sensitive products that are unstable in solutions. This is an important innovation in the field of Medical, Beverage, Food, Personal Care and Chemical Packaging Technology.

A patented revolutionary container closure with a delivery system that features an internal multi-cavity design that stores: liquids, powders, gases, granules or tablets. Examples of materials that may be contained include aromas, syrups, extracts, flavors, effervescent tablets and many sensitive ingredients that can be successfully stored completely separate from air and liquid until right before consumption or use. It is now possible to store ingredients separately in a dry or liquid state, and then mix them with the main container ingredients immediately before it is used.

The patented bottle closure technology is available with a single or double chamber, where one or multiple ingredients may be stored separately until the time of use. The double-chamber model has two separate independent chambers. The contents in each chamber remain separate from the contents of the main container, as well as the second chamber until the activation. This protects the shelf life of each separately contained substance, including those contained in the bottle closure and the primary container. The technology increases the shelf life of many products which are not stable in aqueous solutions. Through this revolutionary enhanced technology the container closure allows for the storage of these types of substances in an air-tight stable environment until the closure is activated.

The bottle closure stores ingredients inside one to three air-tight chambers and by turning the top 350° degrees, the bottle closure is activated and the ingredients are released. This turning motion cuts the seal inside the chambers, releasing ingredients into the primary container allowing for the mixing of the contents at the desired time of use. The rotation of the closure activates the bottle top that results in an immediate release of the substance inside the chamber. An accurate dose of ingredients are able to enter the primary container and mix upon the activation of the dispensing container closure.

The bottle top technology is versatile and may be used in conjunction with a variety of containers produced in plastic and glass. Since the bottle closure is activated by twisting the device, the consumer can actually see the ingredients dispensing into the product stored in the main container. This innovative, low cost functional device brings new solutions and differentiation in the way of packaging. It can be used in many different applications including Medical, Beverage, Food, Personal Care and Chemical. Now through this technological innovation, many new products will be born or existing ones will be reinvented in the categories of:

• Medical: aspirin, vitamins, vaccines, cytotoxic medicines and other products to deliver zero operator error under sterile conditions.

• Beverages: water, sports drinks, fortified beverages, beer, spirits, dairy and other convenience drinks.

• Food: baby formula, salad dressings, sauces and many other types of condiments.

• Personal Care: hair coloring, cosmetics, sensitive treatments for the skin, hair and body that are used in the beauty industry.

• Chemical: Products that cannot be mixed together until the time of use including two-part resins, glues which activate with catalysts, agricultural, fluids cleaning acids, household detergents and automotive oils.

Product Features and Benefits:

The bottle closure technology is ideal for numerous industries and for various materials. Sensitive ingredients can be stored separately; Ingredients combined immediately before consumption; Minimal operator error; Increased shelf life; Security proof measures; Reduced contamination profiles; Inexpensive to manufacture; Extensive target market; Revolutionary and Easy to use; Versatile and can be used in conjunction with a variety of different types of containers.

This bottle closure technology is far superior to any other invention of its type, because it has the ability to store liquids, powders, gases, granules or tablets separately, thus ensuring an air-tight stable environment. The ingredients are stored separately until the device is activated, which is typically immediately before consumption. This keeps ingredients from degrading, losing their effectiveness as well as increasing shelf life.

Product Specifications:

The bottle closure technology is comprised of an internal multi-cavity design; it stores liquids, powders, gases, granules or tablets and has 1, 2, or 3 additional chambers. The dispensing closure includes two injection molded components: One is filled with substance, second is the aluminum laminated induction foil sealing the ingredients. Activated by turning the top 350° and cutting the seal inside the chamber this then releases the ingredients into the main container. The bottle closure is made out of plastic and in numerous sizes including 30 mm up to 150 mm in diameter, depending upon the product it is intended for.

Next Generation:

This new and exciting technology is the biggest breakthrough in packaging dispensing closure mechanisms and will revolutionize what can be delivered as product in the future. For example the next generation of health and wellness beverages that will modernize the way the industry manufactures nutritional beverage supplements throughout the world in PET and glass containers by storing time sensitive substances can now be held in a dry state avoiding contact with the beverage until it is activated as it now makes it possible to release vitamins into the beverage allowing for a fun user experience and the freshest, most powerful way possible for consumers to enjoy immune-boosting supplements in an effervescent beverage which will be the future of beverages.

Scientific studies have clearly demonstrated that vitamins are not stable in beverage products and that the longer they stay in contact with liquid, the weaker they become. Such sensitive substances begin to degrade and lose potency almost immediately when mixed with the liquid at the time of packaging. In addition, shelf life and exposure to light promote further loss of their potency creating a rapid decrease in their original value.

In developing the bottle closures technology we forever change the future of beverages by addressing this problem. It has produced the optimal solution to protecting the ingredients and keeping the original value of the substances that you want to dispense into the container by keeping the ingredients completely dry and fresh right up to the time of consumption. It is the innovative mechanism that stores it in the container protecting it right up to the point when it is opened thus activating the dispensing system and delivering the optimal level of the vitamins’ effectiveness. This is the synergistic result of new technologies combining in a product that offers consumers the most potent levels of vitamins and minerals attainable in a beverage with the added benefit of convenience. Through this breakthrough technology the world will see a proliferation of functional beverage products based on this new, innovative invention globally.

Frequently Asked Questions:

Q. WHAT DOES THE BOTTLE CAP DISPENSING CLOSURE DO?

A. It stores sensitive ingredients needing protection from moisture, light, time, and liquid. This can now be held in a dry state avoiding contact with the base liquid until the top of the closure is turned which initiates the mixing process.

Q. HOW DOES THE BOTTLE CAP TECHNOLOGY WORK?

A. It is a patented dispensing closure that was specifically developed to contain different types of substances against harmful gases such as oxygen and is completely watertight. With the bottle closures technology, liquid-sensitive ingredients are not dissolved in the product until it is activated just before it is used or consumed.

Q. WHAT HAPPENS ONCE THE BOTTLE CAP IS ACTIVATED?

A. The rotation of the closure activates the closure which results in an immediate release of the substance inside the chamber and the ingredients are able to enter the container and mix accurately with the primary carrier.

Q. WHY IS IT NECESSARY TO KEEP PRODUCTS SEPARATE?

A. Scientific studies have shown that certain products like vitamins lose their effectiveness over time. This deterioration process continues to occur with exposure to moisture, light and heat and there are many other sensitive substances that cannot be mixed before they are ready to be used.

Q. WHAT TYPE OF SUBSTANCES CAN THE BOTTLE CAP DISPENSE?

A. The technology can facilitate dispensing materials such as liquids, gases, solids, tablets, powders or granular materials into liquids or other substances held in the container.

Asking price:

Make an offer

Make an offer

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2025-11-09 16:52:16, Patent Auction Time.

Patent publications:

Patent publications: CA 2536258

CA 2536258 Great invention

Great invention