Home List your patent My account Help Support us

Furniture assembly system with automatic buttons

[Category : - DESIGN PATENTS- Furnitures]

[Viewed 1507 times]

simplifying the assembly and disassembly of objects.

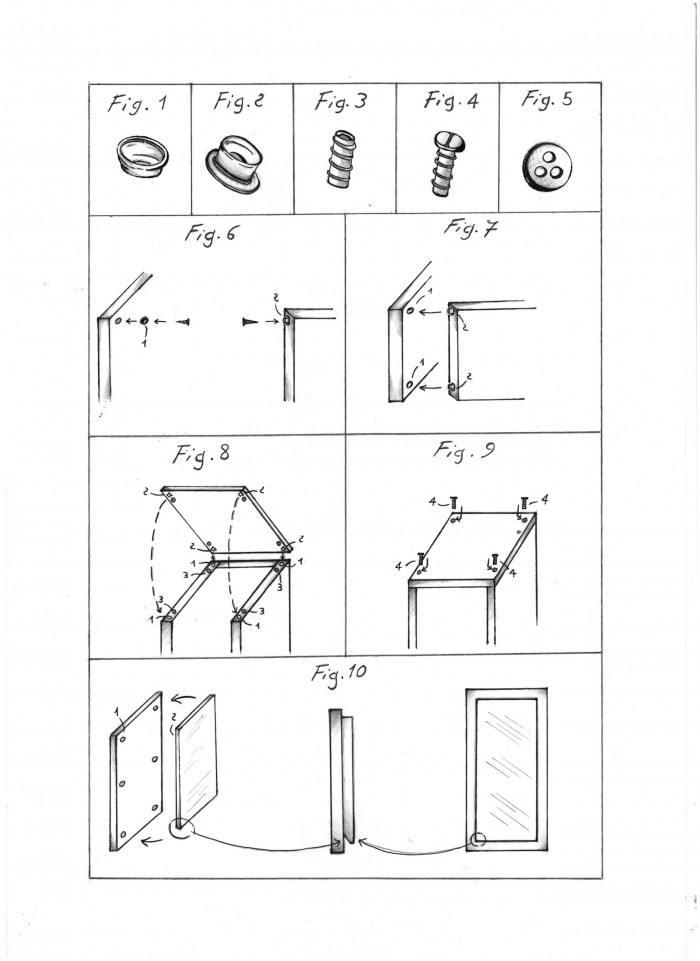

This system will apply it to furnishing solutions; generally the heavy snap buttons are divided

into four parts (head - spring - algorithm - knurling). Using only the spring (FIG 1) and the

knurled (FIG 2), already applied to the panels to create the classic male-female system (FIG 6).

This makes the assembling more intuitive, simple and fast, with the possibility of multifunctional

solutions. The modular objects, once assembled, will have a safety lock with bolts (FIG 4) and

nuts already inserted into the panel (FIG 3) so as to avoid the disassembly of the object in case of

accidental impact. Only a classic screwdriver is necessary to tighten the safety bolts.

It is also possible to use this utility model to overlap panels (FIG 9) by hooking elements of

furniture such as a mirror or an image. In this case, safety bolts are not necessary, and to facilitate

the separation of the furniture components one of the four corners must simply present a 45

degree smoothing. (smussamento)? / be on a 45 degree angle.

The numbered drawings serve to show how very few accessories are needed for this system and

to explain the mechanism, examples will be shown.

The traditional assembly systems, over the years, have been increasingly simplified, trying to

meet an ever-increasing category of users; however, even today, any assembly system requires

the use of tools and / or accessories, which can make assembly difficult for inexperienced users.

Even the dismantling phase can be difficult and not immediate for less experienced people.

Furthermore, in the case of disassembly and subsequent reassembly, both the panels and the

fastening elements such as screws and inserts are subject to deterioration due to wear and to

accidental breakages.

The most modern assembly systems based on magnets applied to panels, which are based on a

principle similar to that of the present utility model, have some contraindications that should not

be underestimated. In fact, magnets create magnetic fields, which can cause disturbances to

people depending on the exposure. Furthermore, in the case of even minimal chipping of the

magnet, the latter if ingested could cause serious health damage. The European regulation dated

July 21 2008 concerning toys containing magnets, the obligation to declare the health risks of the

material used is specified.

The utility model described below do not present health risks as the material used are ionized

steel, which does not create magnetic fields, can not splinter and does not create powders harmful

to human health.

The purposes of this utility model are as follows:

a) minimise the use of tools and accessories during assembly and disassembly;

b) increase self-management of furniture assembly, reaching a wider and inexperienced public;

c) to preserve the components of the furniture components intact, which during assembly can be

damaged by incorrect insertion of screws or inserts, with consequent difficulty or impossibility to

complete its assembly;

d) as in point 2, to safeguard the furniture components during disassembly for subsequent

reassembly, reducing in this case the risk of wear or damage to parts of the accessory itself;

e) avoid the use of substances harmful to humans and the environment without losing practicality

and effectiveness.

The usefulness of this model is achieved by a furniture assembly system with automatic buttons.

The heavy snap button system consists of four parts: head, spring, alga and knurling. The idea is

to apply this system using the spring components (FIG.1) and knurling (Figure 2). When the

furniture item is assembled, the elements (spring and knurling) will already be applied to the

panels, thus creating the classic and automatic male / female system.

This will make the assembly more intuitive, simple and fast, with the possibility of

multifunctional solutions.

All the modular objects, in addition to the spring and knurled couple, have a safety closure

composed of bolts and nuts inserted into the panel. This safety closure prevents the object from

being disassembled in the event of accidental impacts.

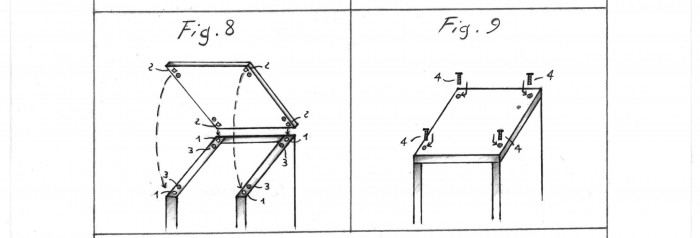

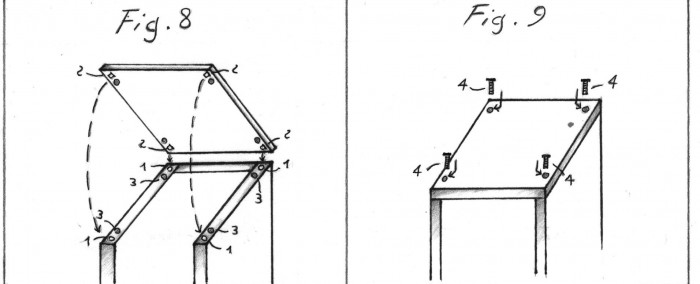

The assembly and disassembly can be done manually or with the help of a rubber hammer to

facilitate the assembly of the panels. The bolts are inserted in the appropriate closing holes of the

structure (FIG 8), tightened by a classic screwdriver.

Further characteristics and advantages will appear clearer from the description of the assembly

system, illustrated by way of non-limiting example in the accompanying drawings, in which

Figures 1 and 2 are the main elements, i.e. spring and knurling. Figures 3 and 4 are the safety

closing elements, ie. nuts and bolts.

The example refers to wooden panels (2 cm thick), in which springs and knurling elements have

already been applied at the joint points that are highlighted. (FIG 6)

The spring and the ionised steel knurling, in this example (wooden shelf), preferably have a

diameter of 14mm. When the button with heavy click is closed, the resistance is minimal, on the

contrary, detaching the two parts is simpler as there is a small ring in iron or steel inside the

springs which creates excellent resistance in the phase of detaching the two parts.

The assembly of the spring can take place in advance by inserting it into a predetermined

alloggio?, equal to the depth of the spring, and subsequently fixing it by applying a strong grip

glue and inserting a special flat head screw to avoid creating thicknesses that would cancel the its

use. Similarly, the knurling should be fixed in the corresponding furnishing accessory with the

same materials (glue and screw) (FIG 5). In case of industrial assembly, spring and knurling can

be fixed to the panels through the use of industrial glues and screws for greater strength and

precision, panels of different material (aluminum, iron, etc.) can also be used, that is any strong

material. In both cases the end user will have an assembling product with the spring (FIG 1),

knurling (FIG 2) and nuts (FIG 3) already fixed, that simply have to be assembled in the order

indicated. (FIG 6 and FIG 7).

Once the modular object is assembled, one proceeds to the safety closing by means of simple

bolts of the same size that are inserted in correspondence with the nuts. (FIG 8) The bolt a length

equal to the sum of the panel thickness 2 cm, and to the depth of the nut 2 cm; in this case a 4 cm

bolt is necessary. The type of nuts / sleeve changes depends on the material of the panel, in this

example threaded inserts will be used. (FIG 3)

The invention can also be used for fixing decorative elements.

In fact, using the same system with automatic buttons based on the spring and knurling elements,

t is possible to hook and overlap flat surface objects; in this case the element to be hooked (ES a

mirror or an image) will not need safety bolts, but simply one of the 4 corners must have a

smoothing to facilitate the detachment of it. (FIG 9)

Financial information

Nice people interested in buying.

My patent is intended for the sale to a full license. I'm the owner of 100%, any partnership with third persons and company.

I'm selling with a heavy heart because due to my commitments around Europe, I wasn't able to realise my project.

The patent will be sold to who will be willing to agree the sales price.

Thanks for your time.

Best Regards

Vittorio date

Interior Designer

Patent publications:

Patent publications:No publication

Asking price:

125,000 USD

125,000 USD

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2025-12-16 9:22:06, Patent Auction Time.

Great invention

Great invention