Home List your patent My account Help Support us

Internal combustion engine with Variable Valve Lift System

[Category : - Automotive Accessories ]

[Viewed 4049 times]

This system is a mechanical transmission having the capability of varying the lift of the intake and/or exhaust poppet valves while the engine is running and when varying its working conditions. Said variations being continuous and within wide limits.

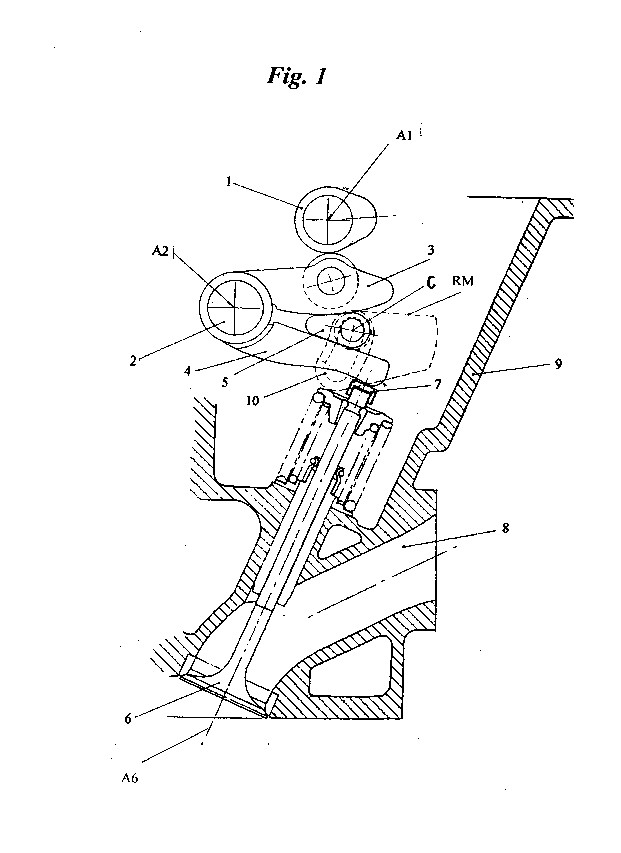

The mechanical transmission includes (see Fig. 1) a regulator mechanism (RM), with two slotted holes (10), and an actuation mechanism composed by:

- a primary oscillating lever or finger follower (3), in contact with the cam (1) actuating the lift of the valve;

- a secondary oscillating lever or finger follower (4), directly acting on the poppet valve (6);

- a wedge-shaped slider device (5), with a bore fitted with a roller free to rotate and having its ends protruding from it. The ends of said roller are engaged and guided by the slotted holes (10) of the regulator mechanism. Said slider is interposed between the two oscillating levers and transmits the movement from the primary oscillating lever to the secondary one. Said slider, by sliding back and forth during the valve's lift, actuates - depending on the rotation of the regulator mechanism around the axis C - the variation of the poppet valve's maximum lift.

The regulator mechanism is operated by a suitable system (e.g. an electric engine driving a worm gear) in order to modify - according to the engine working conditions and to the defined engine regulation strategies - the angular position of the slotted holes and hence the movement of the slider, when the cam is lifting, with respect to the two oscillating levers, in such a way actuating the variation of the transmission characteristic from the cam to the poppet valve.

The primary application of a VVLS like this one is for maximizing the volumetric efficiency of the engine over the speed (maximum torque/power vs. revs), which is physically impossible with a fixed lift of the valves. This gives also the chance of downsizing the engines, which is one of the most effective way to reduce the fuel consumption, and hence the CO2 emissions (and also the other emissions) from any kind of application of the internal combustion engines.

By using this system over the speed and load it is possible to control the amount of air aspirated by the engine in any working point. In such a way, the throttle valve may be eliminated and, in fact, the only one solution with continuous variation of the lift on the market (BMW Valvetronic) performs in this way.

Moreover, the application of this invention to the exhaust valves to reduce their lift to small values when braking represents an effective way to obtain a servo-braking or retarder function.

By varying the maximum lift of both intake valves there is the possibility to manage the dynamics of the intake air stream in the combustion chamber (swirl and/or tumble), which is of interest for the direct injection Diesel engines and also for the gasoline engines, particularly in the case of GDI (Gasoline Direct Injection).

By varying the maximum lift of the exhaust valves it is also possible to modulate the internal EGR (Exhaust Gas Recirculation), which is of interest for the reduction of NOx emissions.

As a further option, the counter clockwise rotation of the regulator mechanism may be brought up to zero lift, which will keep the valve always closed. Such a working condition has the potential to be used for the following purposes:

- To get the modular working of the engine, which means the possibility, when working at part load, to deactivate some of the working cylinders (e.g. 4 cylinders of a V8), by keeping its valves always closed. In this way, the active cylinders will work with higher efficiency, with benefits on the fuel consumption and on the emissions.

- To get the VCM (Variable Cylinder Management) of the combustion engines used for hybrid propulsion systems. This solution, which has been firstly demonstrated by Honda with their well known V-TEC (the first stepped Variable Valve Lift System on the market), consists in deactivating all the cylinders when decelerating and braking, improving in such a way the energy recovery by the motor/generator replenishing the storage battery.

To be noted that, with this invention, when deactivating some cylinders, the friction losses of the excluded valve trains are reduced to a minimum, because, when the valve lift is zero, the cam will rotate without pushing on the follower. This is not the case with other variable valve lift solutions, e.g. some of the electro-hydraulic types, which increase the parasitic losses when reducing the lift, due to the increased pumping losses of the oil by-passed by the valve lift controlling electro-valve.

In general it may be said that the solutions of Variable Valve Lift for internal combustion engines already in production - just one performing the continuous variation of the lift , but many under study - demonstrate that probably this is one of the most important technological issues regarding the evolution of modern internal combustion engines. This is further demonstrated by the already effective joint venture of two major Automotive Companies (BMW and PSA-Peugeot Citroen) for the production of a new line of engines of medium/small capacity incorporating the BMW Valvetronic VVL, which confirms that the benefits greatly overcome the additional cost and complexity.

Iwill be glad to provide any interested person with the full text of the patent and also with an additional technical description, which should give the chance to better understand the working principle of the invention and its potential applications.

For full decription of the patent look at WIPO and ESPACENET sites.

This invention has not been sold or marketed up to now, and there are no other pieces of associated intellectual property.

I am available to consider selling or licensing this invention.

Addendum (October 25th 2009):

The recent merging of FIAT with Chrysler is also based on the transfer of innovation from the Italian Company. The most important one is no doubt the electro-hydraulic MultiAir Variable Valve Lift System (original FIAT’s Patent), which is going to be introduced in the Chrysler engine line. This further demonstrates that this solution represents the most effective way to improve the performance and reduce the emissions - including CO2 - of current internal combustion engines. The invention herewith described is capable to reach the same results with a simple and effective purely mechanical actuation.

Luigi Conti

Corso G. Galilei 34

10126 Turin Italy

E-mail: [Use the button below to contact me]

Patent publications:

Patent publications: No published information

No published informationAsk the inventor for a copy of the filed application

US 7665434

US 7665434 EP 1880087

EP 1880087

Asking price:

Make an offer

Make an offer

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2025-12-15 20:22:21, Patent Auction Time.

Great invention

Great invention