Home List your patent My account Help Support us

Cost and Environment Effective Waste-to-Energy Plant

[Category : - CHEMISTRY- ELECTRICITY & LIGHTING- RENEWABLE ENERGY]

[Viewed 4420 times]

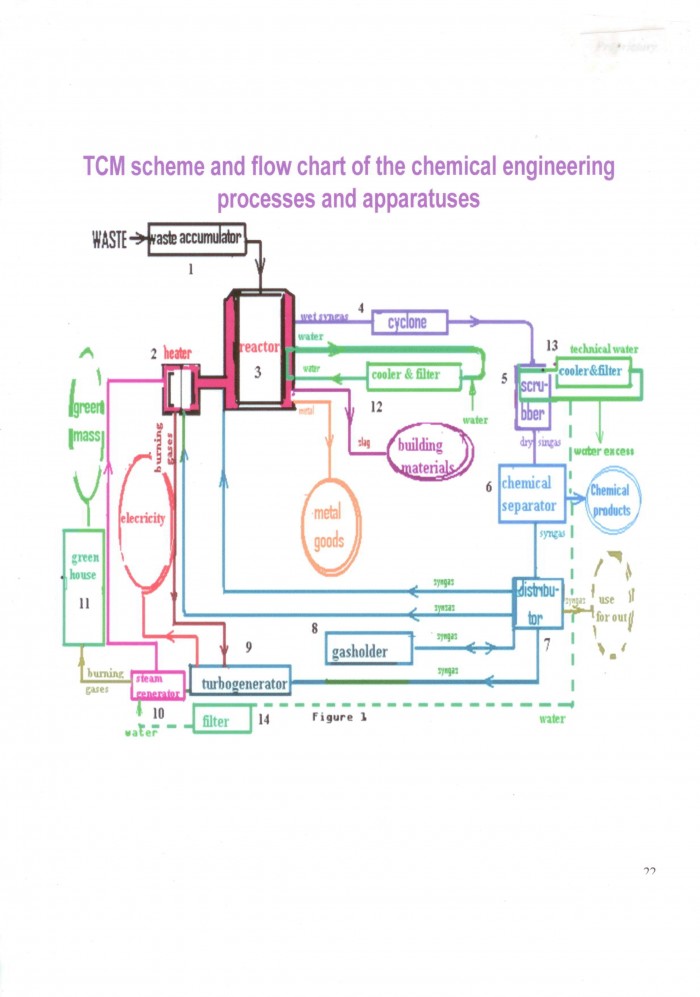

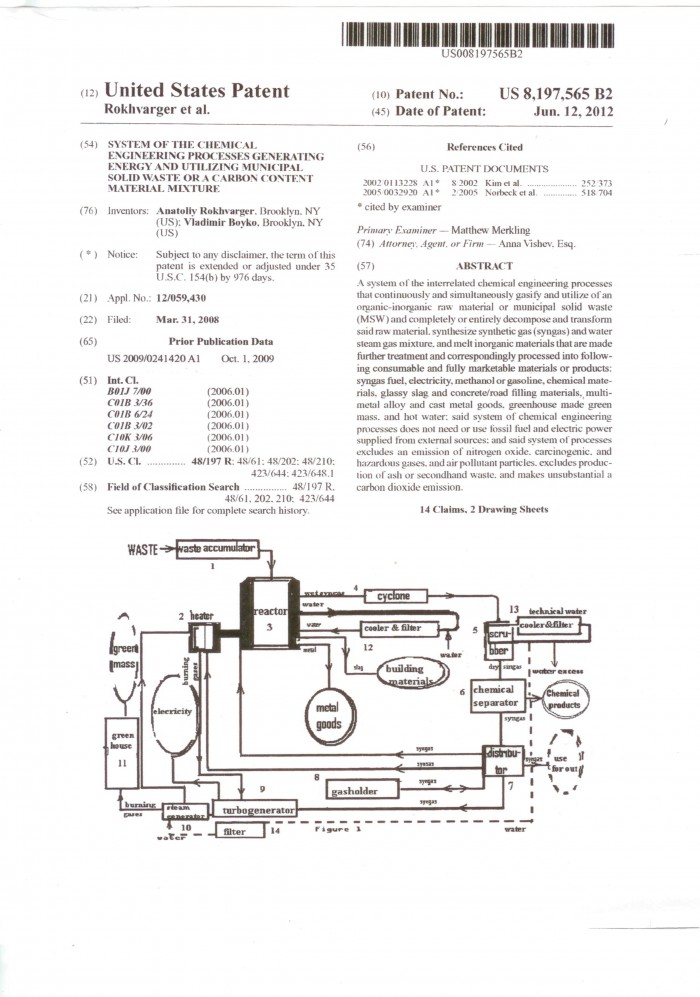

To adjust self-sustainable biomass pyrolysis process,for gasification and recycling organic/inorganic mixtures of MSW, we invented superefficient Thermo-Chemical technological Method (TCM) and created US Patent # 8,197,565, “System of the chemical engineering processes generating energy and utilizing municipal solid waste (MSW) or a carbon content mixture". The patent defines major parameters of construction and operation of the well profitable and clean TCM-WTE plant, which altogether provides superefficient and clean gasification of organic part of MSW and complete recycling (utilization) of the inorganic part of the versatile feedstock mixture including renewable MSW.

The patent defines major parameters of construction and operation of the well profitable and clean TCM-WTE plant, which altogether provides superefficient and clean gasification of organic part of MSW and complete recycling (utilization) of the inorganic part of the versatile feedstock mixture including renewable MSW.

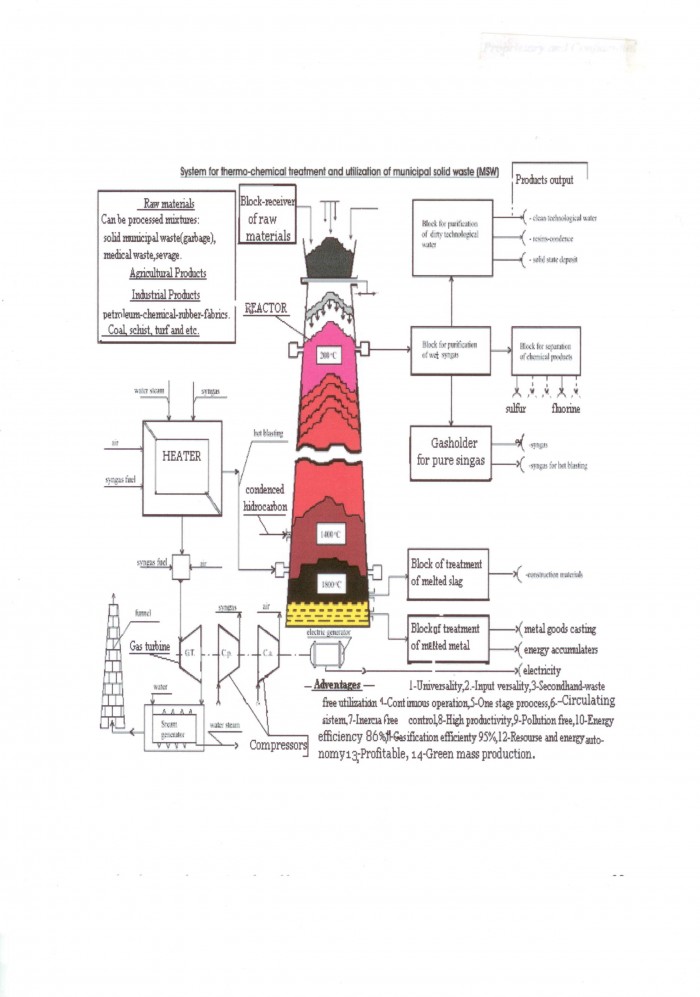

In difference with traditional pyrolysis systems, invented TCM-WTE plant gasifies MSW and other carbon content feedstock in cupola-shaped column reactor at 1550 0C – 1750 0C and 4 atm – 6 atm steam pressure. At this temperature, water molecules dissociate on oxygen and hydrogen. Therefore, TCM-WTE plant produces huge volume of synthetic gas (syngas), which on 50/50 in weight percents consists of carbon oxide and hydrogen gases. An excess of the produced syngas uses to overheat steam in special heater. Then overheated steam returns in the cupola reactor to provide required temperature. The major part of the produced syngas burns in electro-turbine to generate power. Simultaneously with organic gasification, at temperature >1550 0C all inorganic materials melt in to glassy slag and multi-metal alloy that form in the bottom part of the same cupola reactor two separate liquid layers.

TCM-WTE plant provides 26 listed below advantages, as:

1) completely recycles 75000 – 125000 ton per year of sorted or unsorted MSW that produce 17250 – 26000 households or 75000 – 125000 residents and day-time visitors/workers of the town or city district;

2) gasifies the organic part of MSW into syngas with high calorific value 3600kcal/kg;

3) can process any solid feedstock mixture with calorific value more 1200kcal/kg;

4) can generate 0.7 – 2.3 MW-h from one ton of other feedstock with calorific value 1780 – 6000kcal/kg;

5) in depends on a feedstock productivity and an average calorific value has power capacity 8 – 26 MW or 17 MW for typical urban waste and 100000 customers/residents;

6) can annually supply power to 17,250 – 26,000 households or 75000 – 125000 town residents and day-time workers,

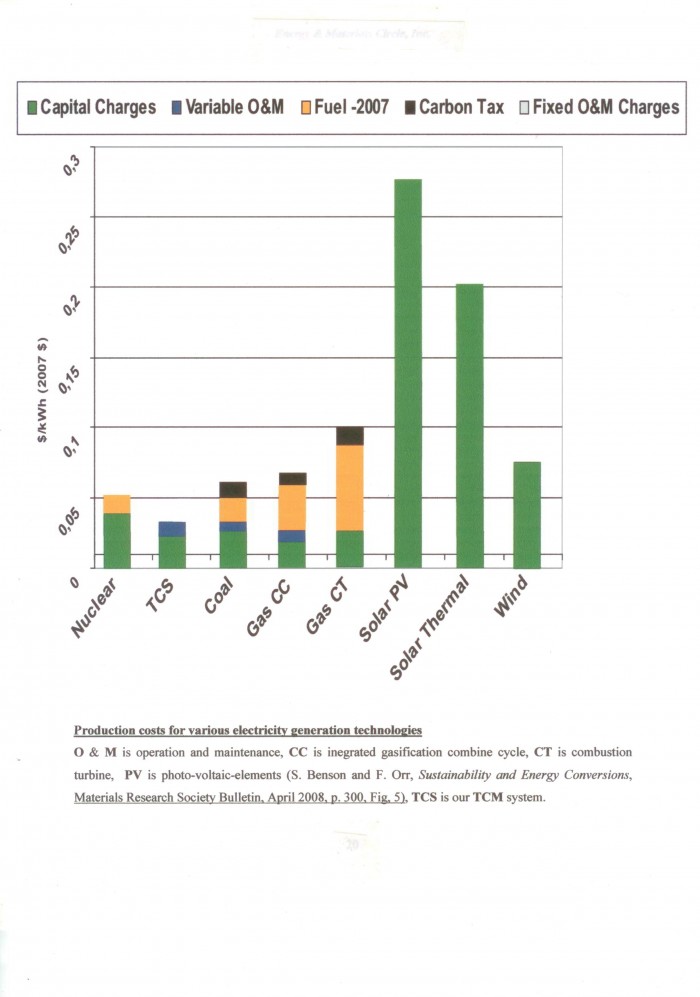

7) provides low and well competitive operational electricity cost, as $0.03/kW-h, which makes viable commercialization process;

8) makes electricity “self-supplying” and electricity independent 17,250 – 26,000 households or 75000 – 125000 town residents and day-time workers;

9) recycles on 17% more carbon energy than IGCC and on 30% than coal power plants;

10) annual supply hot water to 8000 – 12,000 households or 55000 town residents;

11) do not produce dioxin, furan, nitrogen, methane, sulfur oxides and soot emissions;

12) produces carbon dioxide emission only in result of syngas burning in electro turbine, which totally less in comparison with IGCC technology on 50% and on 75% in comparison with coal combustion power plants and waste incinerators;

13) makes possible utilization of 90% emitted carbon dioxide gas for vegetables growing in onsite greenhouse since burned in electro turbine syngas is clean (no poisoning gases);

14) self energy sustainable process do not consume external fuel; this makes TCM-WTE plant profitable

15 has a magnetic separator, which extracts iron items from initial feedstock;

16) produces 2000 – 4000ton/year of metal alloy goods using onsite cast-metal shop to supply local customers;

17) produces 12000 – 17000ton/year of hygienically clean glassy slag, which, after grinding, shall be used for home and road construction purposes as concrete filling material,

18) do not produce ash and other secondhand waste, as IGCC plants and incinerators do, (so no ash needs to be disposed of);

19) keeps clean land and air of the town or city district;

20) being environmentally clean, allows TCM-WTE plant system be clean and cost-effective “reliability must-run” (RMR) local electricity generation station;

21) being environmentally clean, allows TCM-WTE plant to locate within urban area, which reduces waste transportation expenses and pollution from trucks otherwise used for this purpose;

22) operates creating 40-50 new jobs;

23) makes town and city waste-free and fossil fuel free and with clean air;

24) makes 17250 – 26000 households or 75000 – 125000 town residents and day-time workers self-reliable (self-supplying) for household electricity, hot water, some simple metal goods, road and concrete gravel and a some amount of vegetables or flowers.

25) complete, clean and efficiently recycles urban MSW or specific wastes, as plastic, cartoon, agricultural, food production, garden and forest wastes, home demolition waste, used asphalt, used tires, ash dumps, and old landfills.

26) complete and efficient organic gasification and inorganic recycling (conversion in useful products) make unnecessary very expensive waste sorting and separation of cartoons, plastics, resins, glass and metal cans.

Financial information

Prototyping: 1. The prototype of the TCM system 14 months successfully operated at the Salavat Yulaev (former Shevchenko town, f. USSR, now Turkmenistan) plant, which gasified peat and asphalt.

2. At High Temperature Institute of f. USSR Academie of Science 20000 hours operated a heater providing steam temperature 2300 0K .

TCM-WTE system validated by:

1) gold medals and diplomas received on environment and energy international conferences and exhibitions in: (i) Moscow, Russia, 2001; (ii) Genève, Switzerland, 2002; and (iii) Linz, Austria, 2003 and

2) our verbal presentations at professional conferences in (i) Kharkov, Ukraine, April 2010 and (ii) NJ Technological Council, New Jersey USA, May 2011,

Modeling and design: Recently, we provided together with specialists of Retech Engineering company and professors and students of University of California San Diego, Jacobs School of Engineering. There we.,approved feasibility and efficiency of the entire TCM-WTE system, as well as defined detailed parameters of construction and operation of the cupola reactor and electro-turbine. We provided reactor simulation, turbine analysis, Environment impact and economic analysis.

We compared characteristics a) TCM-WTE plant and working now b) combined IGCC and Plasma Arc (PA) plant and c) incinerator plant, as:

1) Annual production capacity, tons: a) 100,000; b) 145,600; c) 100,000

2) Consumption of resources on one ton MSW:

(i) external fossil fuel, kg/t-waste: a) 0; b) 200; c) 200

(ii) technological power use, kW-h/t-waste: a) 250; b) 500; c) 250

3) Capital investment to utilize one ton of MSW, $US: a) 500; b) 856; c) 1,000

4) Municipal expenses to utilize one ton waste, $US: a) 0; b) 60; c) >100

5) Annual pre-tax capital return on investment, which does not include state, municipal and customer tips and other support payments ,%: a) 40; b) 0; c) 0

6) Profit from each one ton of the utilized MSW (without customer fee for MSW collection), $US: a) 200; b) 0: c) 0.

Using, for example, an average MSW composition from four landfills in Connecticut State of the US, TCM-WTE plant can complete and clean recycle 100,000 ton/year MSW, which produce 100,000 residents and daytime town visitors. Said plant can continuously supply 17 MW for 3 cents/kW-h electricity to said 100,000 people, making them energy self-reliable, as well as supply significant part of the consumed hot water, simple metal goods, road and concrete gravel and some vegetables.

TCM-WTE plants would simultaneously solve three growing U.S. and worldwide problems: 1) complete and clean recycling of day-by-day renewable municipal solid waste (MSW) as well as other carbon content wastes; 2) keeping clean land and air of towns and global atmosphere; and 3) substitution of fossil fuel on renewable and cheap energy generation sources.

The estimated US MSW market is $200 Billion. The US-wide implementation of TCM-WTE plants would: a) result in generation of 450 Billion kW-h/year electricity, b) provide 10% decrease of the GHG emission across the U.S. and c) reduce 10 – 12% consumption of the natural gas and coal.

We are looking for an outright sale or a license with royalties and partnerships.

Asking price:

Make an offer

Make an offer

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2025-12-15 12:30:08, Patent Auction Time.

Patent publications:

Patent publications: US 8197565

US 8197565 Great invention

Great invention