Home List your patent My account Help Support us

ADJUSTABLE HEAT EXCHANGER

[Category : - MECHANICAL ENGINEERING]

[Viewed 2069 times]

Financial information

Applications of the patents other than the precise-controlling of heating rates:

1. for quick cooling of fat and fat emulsions .

2. for quick crystallization of sugar from its solution.

since the coolant used may be a cooled water, liquid nitrogen-vapor (preferred), liquid helium-vapor or others, the liquid nitrogen-vapor coolant allows more efficient task of: 1) cooling the viscous materials such as fat and fat emulsions and 2) crystallization of sugar from its solution”. In addition, the liquid nitrogen is cheaper than the liquid helium although the latest coolant is more efficient in cooling.

In this regard, using the N2-liquid vapor/ dry air mixture as an alternative coolant for cold water. Cooling with N2-liquid is more efficient than cold water in treating viscous materials, comprising in particular fat and fat emulsions or sugar crystallization from its solutions. The N2-liquid vapor permits relatively sudden cooling that subtracting the cooling duration significantly. In addition, sudden cooling occurred by N2-liquid vapor for sugar solutions helps sugar to be crystallized in higher yields.

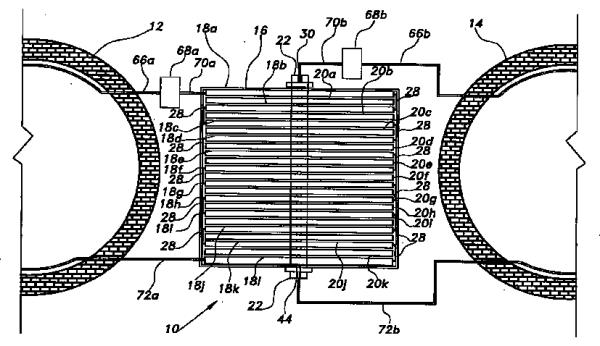

To achieve these targets, two pathways of cooling were shown in Figure 4. In this figure, cold water or N2-liquid/dry air mixture can be used for the cooling process. Regarding to the cold water, a pressurized pump is used to feed it to the inlet hole of the hollow rotatable shaft and returns it to the same source for re-cooling in a closed system.

For the N2-liquid/dry air mixture coolant, filtering air is essential to remove any solid pollutants as well as dehumidifying since the presence of moisture in the nozzles found in the shaft may freeze when using the N2-liquid blocking them and this will prevent the cooling cycle and increase the internal pressure within the fins. The movement of the coolant mixture is adjusted by using a vacuum pump it the terminal end of the hollow rotatable shaft.

Asking price:

Make an offer

Make an offer

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2025-12-30 0:20:05, Patent Auction Time.

Patent publications:

Patent publications: US 9243852

US 9243852 Great invention

Great invention