Home List your patent My account Help Support us

S-Shell Thermal System - Tent Thermal Technology

[Category : - Camping and Outdoors ]

[Viewed 1982 times]

OVERVIEW

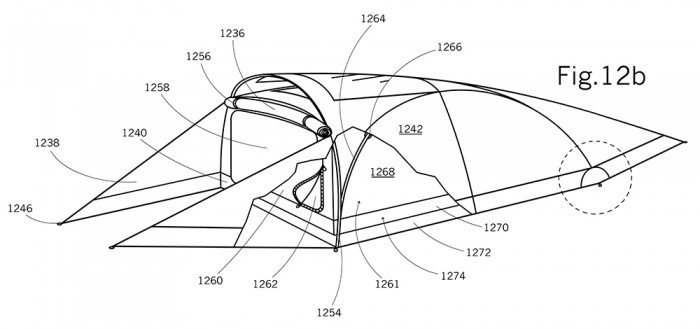

The Thermal System can provide substantial insulation against an array of inclement weather conditions, whilst remaining extremely light and compact. It is designed to be airtight but non-pneumatic. There is also an absence of any fiber insulation that apart from making the article lighter and more compact, it is virtually immune to the effects of moisture accumulation or wind driven rain. The combination of these elements makes it a very reliable insulator. Furthermore, the Thermal System can undergo ad hoc repairs in the field and still perform extremely well.

It is also very versatile, having the potential to perform as effectively under hot dry and humid weather conditions. Day to night temperature differences are more easily managed and ventilation openings are designed to bypass the Thermal System, allowing it to store or release energy regardless of the circulation of fresh air into the tent interior.

FEATURES AT A GLANCE

Warmer in winter, cooler in summer

Very waterproof

Breathable (vapour permeable)

Aesthetically pleasing - appeals to the primary target market

Versatility second to none

Reliability - can be depended on in hazardous/extreme environments

No condensation issues, unlike other single wall tents utilizing similar materials

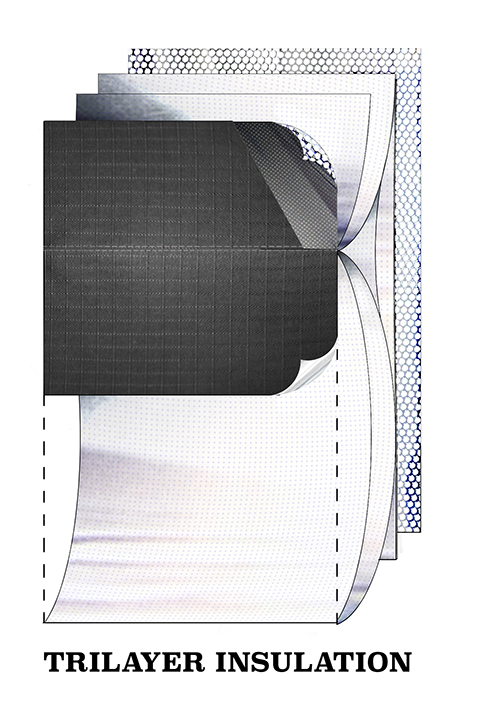

Lightweight, bilayer insulation arrangement equivalent to an synthetic insulator with a meager 1.5cm loft

Easy to maintain, no mildew issues like canvas tents/fast drying

Unaffected by moisture accumulation

PRIMARY APPLICATION OF THE TECHNOLOGY

Outdoor and recreation industry; synthetic lightweight, ultra lightweight, mountaineering, hiking and expedition tents specifically. Could also have usefully military applications, usefulness in marquees and other larger shelters, as well as small shelters such as bivy bags, swags etc.

Including the above, of which is primarily the more intrepid back-country campers and professionals, there is a broader recreational market:

According to the Outdoor Foundation study of more than 30,000 people in the US (2011), the mountain region has the highest camping participation rate, of which a tent equipped with the Thermal System is adeptly suited.

Also, 77% of campers in the US are coupled and that equal amounts of men and woman go camping. A tent equipped with the Thermal System could be appealing to this large general market trend, whereby the invention offers more comfort like glamping, while remaining lightweight and versatile. 'Glamping' is also on the rise.

39% of people in the study said the tent was the most essential camping product and were prepared to spend more on this item than any other.

66% of all campers use tents. 10% more backpack with ultra lightweight or bivy bags (76% of 41 million people who went camping in 2011).

25-54 year olds make up 50% of the camping market. Another 20% are students. This is the age bracket which I believe the Thermal System has the most appeal.

Average income of campers was $75,000-$100,000. Camping appeals to people who are not just looking for a cheap holiday, in fact the main reason (more than 65% of responses) given for camping was 'camping for its own sake'.

In 2011, Americans spent more than $220,000,000 on tents and shelters alone and the industry continues to enjoy steady growth.

THE PROBLEM SOLVED BY THE TECHNOLOGY

The insulation of tents at present is limited to those that are made of materials with inherent insulating properties. These are tents constructed from natural fibers such as cotton or hemp, known ubiquitously as canvas tents. Certain polymers such as polyvinyl chloride (PVC) or other heavy gauge synthetics used in the construction of larger or four season tents are also more insulating due to the thickness and imperviousness of the material. However, these tents are notoriously heavy and bulky, and not appropriate for most recreational purposes. Natural fibers are also slow to dry out after wet weather, making them prone to mildew if not stored properly. Despite their drawbacks, canvas tents are still in wide spread use among camping enthusiasts because of their natural insulating properties and general robustness.

However, it is the lightweight tents made from synthetic fabrics like nylon that dominate the market today. Both consumer favours them and manufacturer alike because they have greater flexibility in design, are easy and fast to set up and more cost effective. They are usually geodesic in shape and made of three elements; an inner tent comprising mesh paneling for fresh air with an integrated groundsheet to enclose said tent from the ground beneath, a frame to support said tent and a weather resistant cover known as a flysheet or rainfly. The rainfly is draped over and about the inner tent and secured near the ground. A standard rainfly is generally quite good at repelling the wind and the rain. However, the synthetic material has next to no inherent thermal properties against the cold of night or heat of the day.

Ultra lightweight tents or adventure tents, which is a relatively new market aimed at more extreme traveling and expedition, has emerged from a mixture of demand and technology. These tents are often made with advanced nylon or polyester materials with additional tear resistant weaves known as ripstop weaves. This enables the manufacturers to use lighter fabrics that can handle a range of conditions, some of which weigh as little as 18 grams (0.66oz) per square meter. Despite the innovation seen in this industry, a solution to improving the thermal properties of ultra lightweight tents has yet to emerge.

In addition to the lack of thermal insulation, lightweight and ultra lightweight tents used for hiking are typically designed with a low profile to combat strong winds, making them just large enough to sit in or sometimes just sleep in. Although compact and lightweight, sleeping within these compact spaces cannot stop radiate heat losses. Sealing the tent up to stop convective heat losses from intruding winds works temporarily until internal air temperatures drop via other means.

On cold nights and particularly cloudless nights, an additional problem arises. Without cloud cover, radiant heat escapes into the upper atmosphere rapidly after nightfall and the difference in pressure between the warmer interior and the rapidly cooling exterior, can condense the warm moist air on the interior surface of the inner tent walls rather than the underside of the rainfly. The result can be very uncomfortable. One typically wakes up in the morning or worse during the night, to find their sleeping bag is damp and sticky. At rest this increases the experience of cold and being damp or wet in cold conditions can lead to hypothermia. It also necessitates the airing out of clothes and sleeping apparel each day to prevent the growth of fungi and bacteria. With a combination of insulation and adequate ventilation however, this problem can be resolved.

Accordingly, there is a need for a tent that can overcome the aforementioned limitations and be truly insulating under a variety of environmental conditions, whilst remaining lightweight and durable.

HOW THE TECHNOLOGY SOLVES THE PROBLEM

Condensation management

During cold weather, the higher indoor temperature of the tent interior is buffered against the outdoor environment by the Thermal System. The vapour pressure differential between the three environments drives moisture vapour out of the tent interior and into the outdoor environment. A hydrophilic (water attracting) membrane on the outward facing side of the inner tent wall pulls moisture vapour through the fabric and into itself, whilst simultaneously performing as an effective gaseous membrane. This vapour condenses on and within the membrane.

However, because the thermal envelope can maintain a higher relative temperature, it can accommodate more moisture vapour and therefore precludes the accumulation of much liquid moisture. Instead, the different vapour pressure of the thermal envelope and the colder outdoor environment continue to move the moisture vapour centrifugally. The vapour passes through the Thermal System and reaches the underside of the rainfly proper. Here the moisture is attracted to the colder permeable fly underside, where it is eliminated via diffusion or capillary action.

During hot dry and moderate humid weather, the same process of diffusion will occur. Condensation build up or sweating on the outdoor surface of the rainfly is a positive indication that the thermal envelope is actively reducing heat loss through the walls of the tent.

Typical vapour pressure differences are much larger than typical air pressure differences. This is the simple principle in which the Thermal System is based and conceived as a highly stable, reliable and effective insulation system, regardless of ensuing weather conditions.

OPERATION OF THE THERMAL SYSTEM

The efficacy of the thermal system works through the combined effects of slowing the radiation of heat through high reflectance and low emissivity, disrupting internal advection and diffusion or convection in a poor conductive airtight or near airtight environment. This essentially creates a thermal reservoir or heat bath around the inner tent rather than simply reflecting heat away or toward the tent interior.

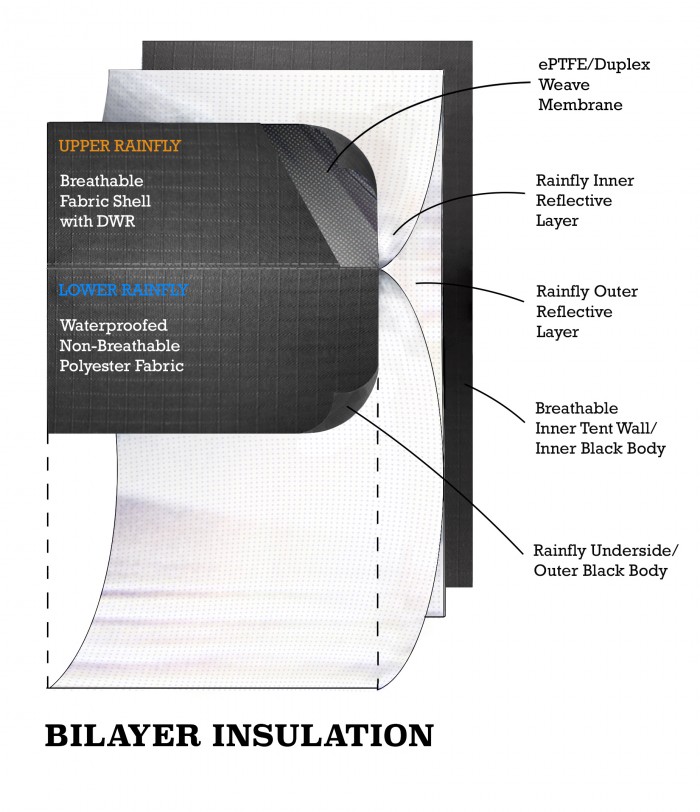

Black walls? (please refer to drawing below)

One version of the Thermal System comprises a ‘Black body’, which acts to reinforce the boundaries of the thermal envelope, behaving as a heat absorber and distributor. Although counter intuitive, the carbon black colourant of the fabric works more effectively during hot weather than a white colourant. A black Fly can reach higher surface temperatures, converting more radiation into heat. This heat can then be easily dispersed by a gentle breeze. On cold days the Black body can be utilized as a passive solar mechanism.

The operation of the thermal system during cold weather

During cold weather, radiant energy emitted from the body of the occupant inside the tent interior first encounters the inner Black body or polyester fabric and is to some degree absorbed and stored therein. The high emissivity of a carbon black dye within the polyester emits at least 81% of that heat to its colder side. Because the air in this area is not particularly turbulent however, the energy in the inner Black body can be inhibited quite effectively.

Once through the inner Black body, heat then enters the thermal envelope proper and is reflected back into the airtight space via the suspended reflective layer(s). Some of this heat is reflected back into the inner Black body and further absorbed and reabsorbed by it. The heat, emitted off the cold side of the reflective layer however, is the primarily disruptive action of heat transfer via low emissivity. Depending on the arrangement, the emitted heat then encounters progressive reflective layers, which agitate the air between them. This process repeats until the entire ‘packet’ of thermal energy is completely emitted out the cold side of the fly.

The operation of the thermal system during hot weather

During hot weather, essentially the reverse occurs. The Black body of the Fly jacket first absorbs incoming radiant heat from the outdoor environment. The heat then encounters the reflective layers, reflecting heat back into the underside of the Fly jacket and is again absorbed by the outer Black body. The low emissivity of the reflective layers impedes heat transfer from penetrating further into the thermal envelope. This heat is further reflected back into the airtight space where it is temporarily housed, whereby slowing the migration of heat into the tent interior. The Black body of the inner tent further impedes heat transfer directly into the tent interior through absorption.

Financial information

Hypothetical

100,000 tents with the Thermal System installed are sold over the lifetime of the patent (roughly 20 years), equating to approx. 5000 units per year on average.

Selling at $300.00USD each.

Equates to $30,000,000USD gross over the life of the patent.

5000 annual sales equates to approx. 0.33% of the market (approx. 1.5 million p/year or 1 in every 200 people in the USA in 2011 purchasing tents for an average price of $150.00USD).

Patent publications:

Patent publications: No published information

No published informationAsk the inventor for a copy of the filed application

Asking price:

Make an offer

Make an offer

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2025-12-17 6:15:36, Patent Auction Time.

Great invention

Great invention