Home List your patent My account Help Support us

Improved Method for Labeling a Microtube

[Category : - CHEMISTRY- Organic Chemistry- DESIGN PATENTS]

[Viewed 4781 times]

Brief Description:

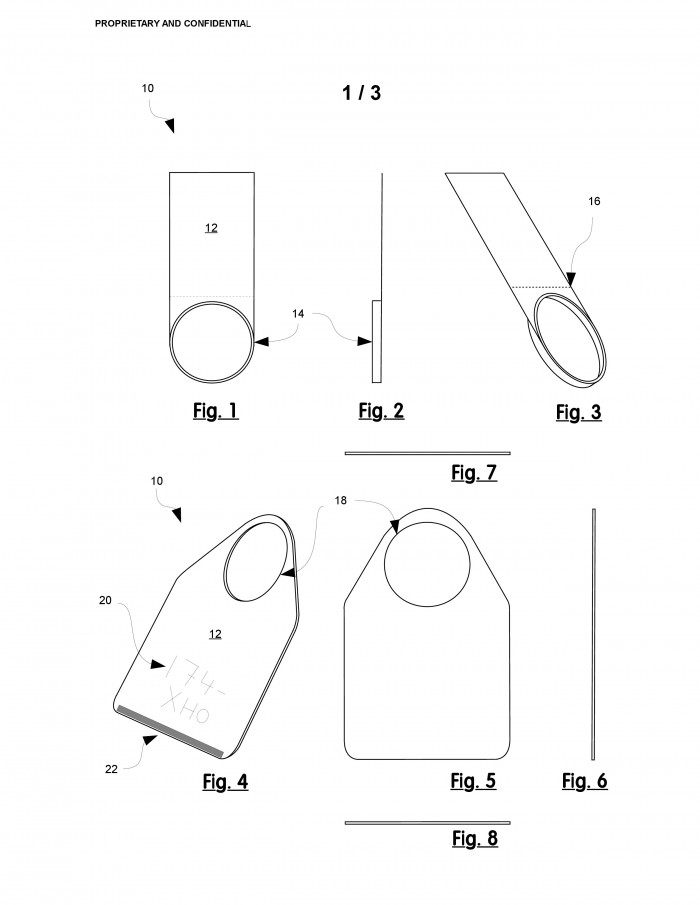

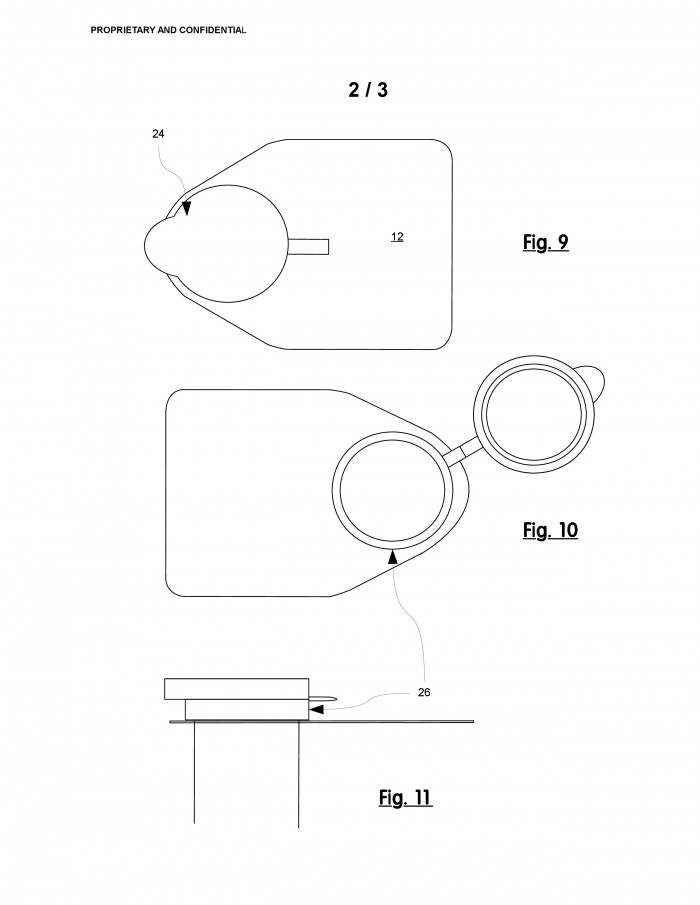

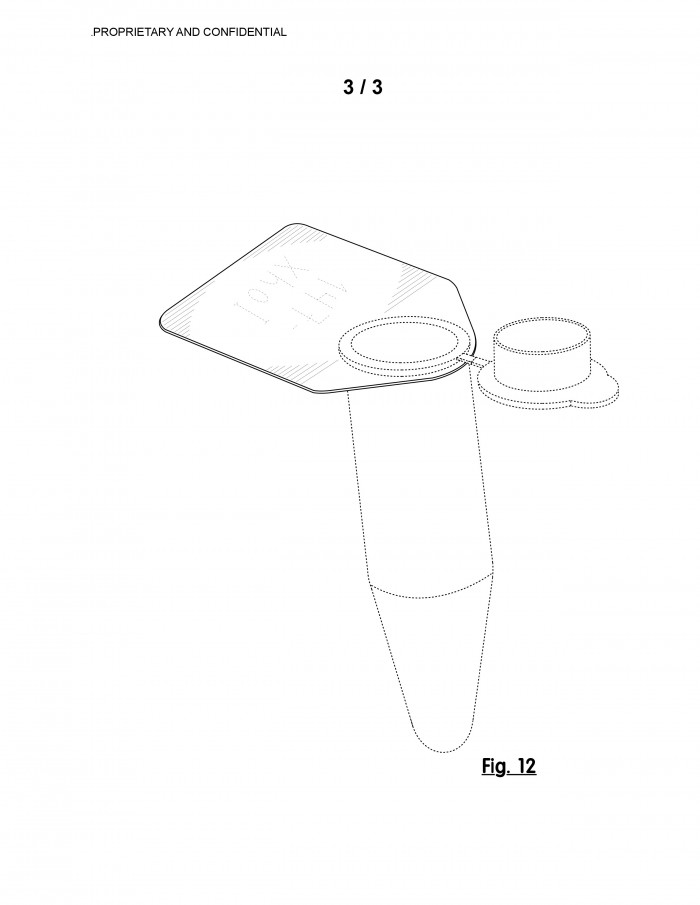

A novel labeling apparatus adapted for microcentrifuge tubes that is durable, easy to use, and does not interfere with laboratory practice. The device comprises a markable panel component and an aperture for frictionally engaging the tube barrel.

Need For:

Microtubes (a/k/a microcentrifuge tubes) are a commonly used consumable in research, diagnostic, industrial, and forensic laboratories. Labeling microtubes has largely been limited to applying identifying information with a writing instrument to the surface of the tube itself, or by fastening an identifier-bearing label thereto.

Problems with existing labeling methods --

Writing:

- writing by hand on the limited and sharply curving tubular surface or cap of a microtube can be unwieldy and tedious.

- the shiny, non-porous surface of a polypropylene microtube can be marked only with writing implements adapted for such a surface

- the marking may be inadvertently scuffed or defaced by repeated handling of the tube during laboratory procedures.

Adhesive Label:

- must be carefully oriented on the tube surface for proper application, and may be subject to abrasion during subsequent tube handling.

- masks the tube contents from view, and may also interfere with inserting the tubes into holding racks and centrifuge rotors.

- may be delaminated or distorted when tubes are exposed to certain extreme laboratory conditions, such as immersion in boiling water baths (at 100 C) and liquid nitrogen (at -196 C).

Embodiments:

Preferably, the device is composed of a suitable stock that is moisture-proof, tear-proof or tear-resistant, and is able to maintain indicia in readable form during typical laboratory practice. Since the device does not rely on adhesives for application, failure of adhesives resulting in delamination in extreme conditions, like steam, boiling water and liquid nitrogen, is avoided.

Candidate materials include, but are not limited to, polyester, PVC (vinyl), polypropylene, and other materials with similar qualities. Such materials offer many of the desired attributes and may be readily die cut. A preferred material would possess a surface or coating suitable for marking by hand or computer.

Additionally, the material may be amenable to computer-directed printing with consumer-oriented desktop printers. The device stock may be pre-cut to a sized portion using die cut methodology and separably laminated to a liner sheet bearing a tacky adhesive surface. After printing, the label is simply separated from the liner and is ready to use. Computer-directed printing would facilitate marking the label with printed or color-coded identifiers, especially in large numbers.

Alternatively, the labels may be arranged on an adhesive liner in tape form. Arranging a plurality of the labels on an adhesive sheet or tape, rather than in loose, individual form, would also aid the user in writing or marking on the panel by hand, and in storing the label until use. As an additional alternative, a plurality of the labels may be arranged on a sheet or tape, separated by perforations.

OBJECTS AND ADVANTAGES:

1. markable component is composed of a material that can be indelibly marked with most common writing implements such as pencils, ballpoint pens, and porous-point pens, as well as being printable by computer-directed methods, or using bar-code technology. Can be marked before being applied to the tube, thereby eliminating the difficulty of marking the tube itself.

2. can be easily, quickly, and securely fastened to a microtube without use of adhesives. The device simply slips onto the barrel of a tube and is frictionally held in place. The label can also be easily removed from the tube, intact and undamaged for preservation (e.g., readily mounted in lab notebook), or reuse.

3. will not interfere with most common laboratory practices involving microtubes. Because the label does not cover the barrel of the tube, it does not mask the contents therein from view, and does not obstruct inserting the tubes in holding racks or centrifuge rotors.

4. provides ample, flat surface for receiving and viewing indicia. Label can be readily viewed when tube resides in holding rack, centrifuge, or water bath.

Asking price:

Make an offer

Make an offer

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2025-12-17 15:10:25, Patent Auction Time.

Patent publications:

Patent publications: US D640327

US D640327 Great invention

Great invention