Home List your patent My account Help Support us

THE WAYS OF USING RECYCLED POLYMER WASTE

[Category : - OTHER- CHEMISTRY]

[Viewed 3902 times]

In line with the forecasts of the UN Conference on Environment and Development, the volume of solid waste by 2025 will increase by 4-5 times. At present there has been accumulated more than 100 mln tons of waste tyres in worldwide. The used tyres are one of the largest-tonnage polymer waste. Only in the EU countries their amount exceeds several tens of mln tons. At the same time, the level of their reuse does not exceed 5 per cent, whereas the recycled rubber could be used as a conductive filler to obtain composite materials for electrotechnical purposes.

In 2008, the volume of plastic waste in Western Europe was totaled 24.9 million tons. The experience of EU countries on controlling polymer waste deposition has shown that the growth of gross domestic product (GDP) and growth of waste are interrelated. The total volume of recycling of plastic waste in Europe in 2008 amounted to 51,3%. The value of recycling for reuse and the burning of waste for energy was 21.3% and 30% respectively. It should be borne in mind that in different countries the situation is different. The strategy of waste recycling has set the priority of recycling for re-use over burning for energy. This priority has been formalized in several European Community Directives. In practice, however, the burning of waste predominates over recycling for re-use them, whereas, according to PlasticsEurope data, it is exactly the increase of the recycling level for re-use allows to do unchanged the volume of the deposited waste. Thanks to that, it has become possible to avoid of the interdependence between the processes of economic growth and plastic waste deposition.

The increase of polymer waste level in the world makes actual the task of its recycling and using of them for the production of new products. Obtaining composite materials on the basis of recycled polymers with various fillers opens the perspective to use them in electrotechnical industry as insulating or conductive materials. Moreover, this kind of materials will be cheaper than the ones that produced at the basis of primary polymers.

As a result our 15 years of work conducted by us, the new composite materials have been obtained and patented. The technology of their obtaining consisting in mincing of the components, choosing optimal compositions, stirring the mixture until the homogenous mass and forming the composites by method of hot pressing has been developed.

The created technology allows us to use recycled polymers to obtain composite materials of electrotechnical purposes with the set/necessary electrotechnical properties. By changing the contents and type of the filler, the manner of its distribution in the polymer matrix, the contact resistance between particles, in this way modelling of the level of interaction of the ‘polymer – filler’, it is possible to vary widely the specific electrical conductivity, thus turning the recycled polymers into conductive, semiconducting, and electromagnetic-shielding materials.

The invention includes using recycled polymer waste (recycled polyethylene, recycled waste tyres) together with electrolytic copper and carbon fiber to produce composite materials for electrotechnical use, as well as electromagnetic shields.

It have been achieved the new and unobvious results from the point of view of technics. With the same amount of carbon fiber, the specific electrical conductivity of the obtained composite material at the basis of recycled polyethylene is in several times larger than that of the material at the basis of primary polyethylene.

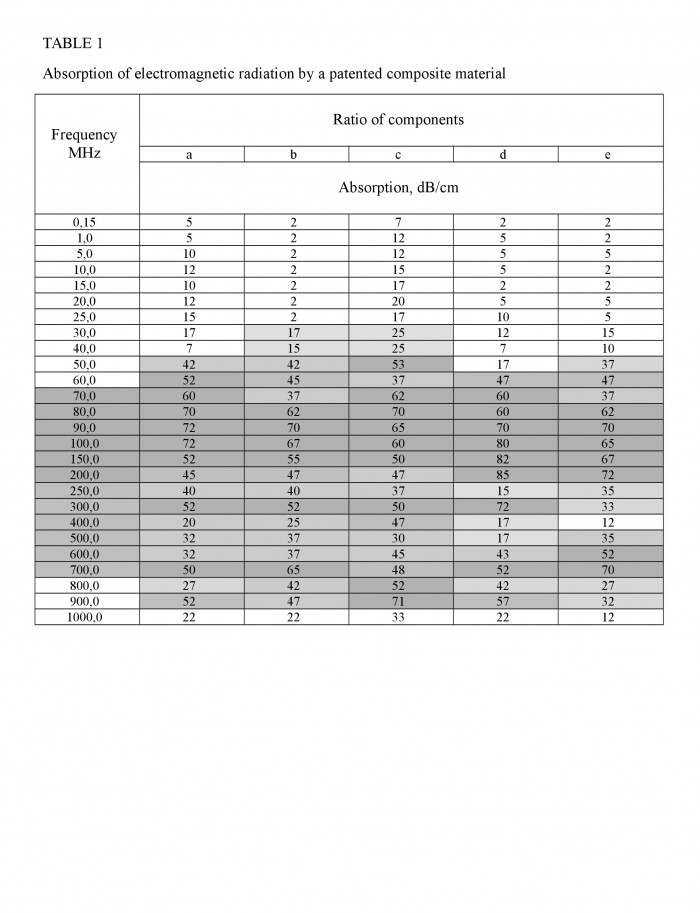

Under the optimal correlation of components, the patented composite materials provide the absorption of electromagnetic radiation ranging from 0,15 to 1000 MHz with the thickness of composite plates of 8 mm, and can be used as electromagnetic shields for effective shielding of electromagnetic waves while using of radio electronic equipment, measuring and control technology, communication radio waves equipment and radar devices.

According to the International Classification of Electromagnetic Waves by Frequency, this range refers to: High RF Frequencies, range limits: 3 to 30 MHz; Very high VHF, range limits: 30 - 300 MHz and Ultra-high UHF, range limits: 0.3 - 3 GHz.

The optimum frequency range under which the maximum absorption of electromagnetic radiation by the composite material is achieved at a plate thickness of 8 mm to a level of 60 to 85 dB is 70-200 MHz, and also some other areas according to the table. See TABLE 1.

Detailed classification of Radio spectrum equipment and technical devices operating in the covered range of 70-200 MHz and wider:

Link

The use of electromagnetic shields will solve the following tasks, among which:

A) information protection (EMR shielding) in premises and technical connection channels,

B) ensuring the electromagnetic compatibility of equipment and devices while they using together,

C) personnel protection (EMR absorption) from the increased level of electromagnetic fields and provision of favorable environmental conditions around working EM devices and radio electronic equipment.

Financial information

The presented patents portfolio for inventions (as a solution for re-use for specific technical needs and tasks) is of commercial interest for large industrial chemical concerns, manufacturers of polymer materials and plastics (polyethylenes), automobile tires, with a certain cycle of their use, from the economic, tax, ecological points of view, namely: easing of the tax burden, special duties imposed on large industrial concerns connected with specificity of their production, leading to environmental pollution.

Patents are put up for sale as the package. The buyer will be given exclusive rights to patents and objects protected by them, technology of receipt and all necessary technical explanations.

Patent portfolio:

1. Zubko V.I. Zubko D.V, The electrically conductive polymeric composite A/ Patent Republic of Belarus №6836/ Registered in the National Registry of 28.10.2004.

2. Zubko V.I. Zubko D.V, The electrically conductive polymeric composite B/ Patent Republic of Belarus №11018/ Registered in the National Registry of 22.05.2008.

3. Zubko V.I. Zubko D.V, The electrically conductive polymeric composite C/ Patent Republic of Belarus №13803/ Registered in the National Registry of 11.08.2010.

Contact:

Patent`s owner Dr. Denis Zubko

e-mail: [Use the button below to contact me]

Patent publications:

Patent publications:No publication

Asking price:

Make an offer

Make an offer

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2025-11-26 4:15:17, Patent Auction Time.

Great invention

Great invention